|

|||

|

|

|||

|

Page Title:

Table 7. Transmission Troubleshooting Procedures. |

|

||

| ||||||||||

|

|

TM 9-2320-361-24-1

0006 00

MECHANICAL SYSTEMS TROUBLESHOOTING - UNIT (Contd)

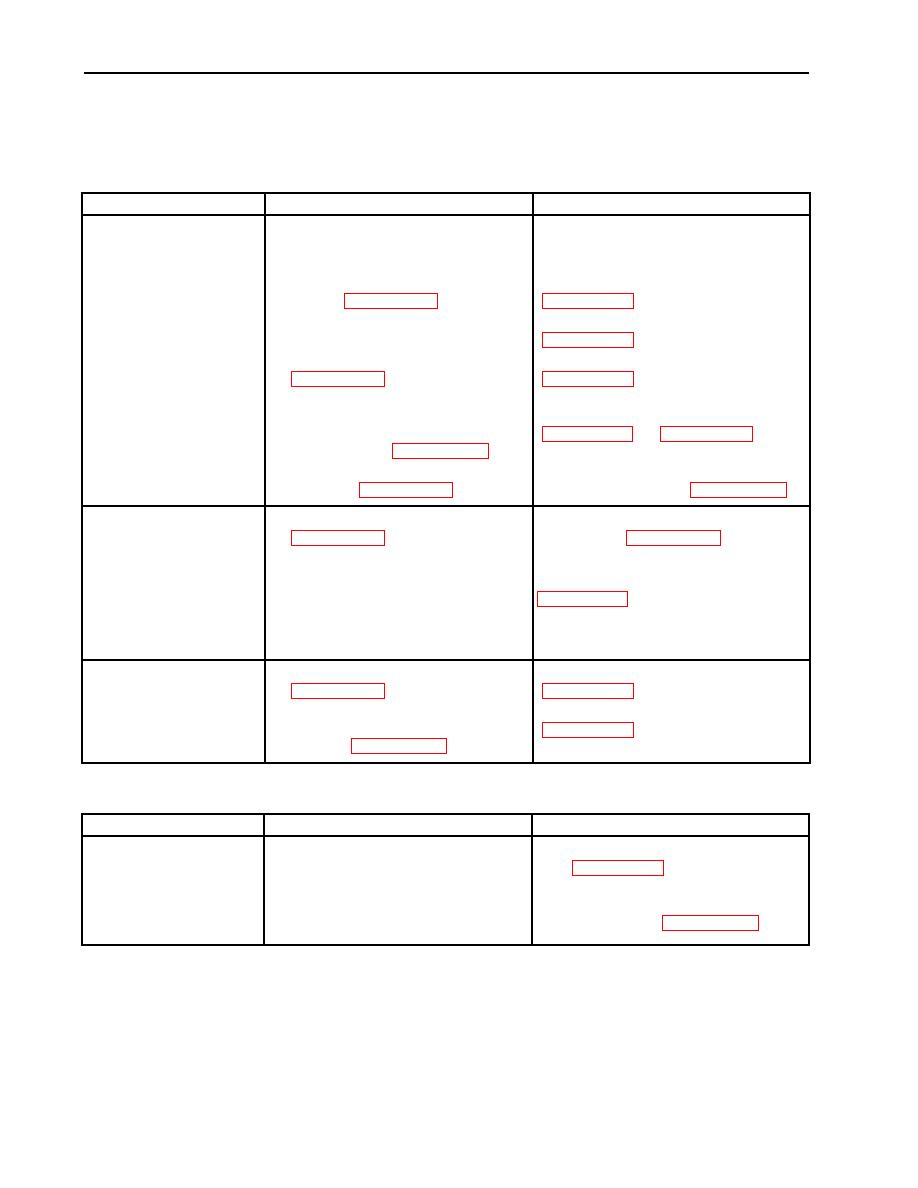

Table 7. Transmission Troubleshooting Procedures.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. TRANSMISSION NOISY 1. Ensure Power Takeoff (PTO) is

If PTO is engaged, disengage.

not engaged, if applicable.

2. Check propeller shafts condition.

If propeller shaft assemblies are

Remove propeller shafts and

worn or defective, repair or replace

inspect (WP 0139 00).

3. Check clutch for proper

Adjust clutch linkage as necessary

adjustment.

4. Check transmission fluid level

Fill transmission fluid to proper level

5. Drain transmission fluid and

If broken gears or metal shavings are

check for signs of broken gears,

found, replace transmission

metal shavings, and

contamination (WP 0020 00).

6. Check mounting of transmission

Tighten loose components or replace

to engine (WP 0132 00).

damaged components (WP 0132 00).

1. Check transmission fluid level

If fluid level is too high, drain to

2. TRANSMISSION LEAKS

proper level (WP 0020 00).

OIL

2. Check drainplug for leaks.

If drainplug is leaking, tighten.

3. Check breather for restrictions.

If breather is restricted, refer to

4. Check transmission output seal

Replace seals (WP 0450 00).

for leaks.

1. Check transmission fluid level

If fluid level is low, add fluid

3. CLUTCH PEDAL WILL

NOT TRAVEL OR

DEPRESS

2. Check clutch linkage to ensure it

Adjust clutch linkage as necessary

is connected and properly

adjusted (WP 0047 00).

Table 8. Clutch Troubleshooting Procedures.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Check clutch pedal free travel.

1. If clutch requires adjustment, refer

1. VEHICLE CREEPS WITH

Clutch pedal should have 1.52 in.

to WP 0047 00.

CLUTCH DEPRESSED

(3.85 cm) free travel.

2. If free travel will not adjust, check

for bent or broken parts. Replace

damaged parts (WP 0047 00).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |