|

|||

|

|

|||

|

Page Title:

Table 3. Cooling System Troubleshooting Procedures. |

|

||

| ||||||||||

|

|

TM 9-2320-361-24-1

0008 00

MECHANICAL SYSTEMS TROUBLESHOOTING - DIRECT SUPPORT (Contd)

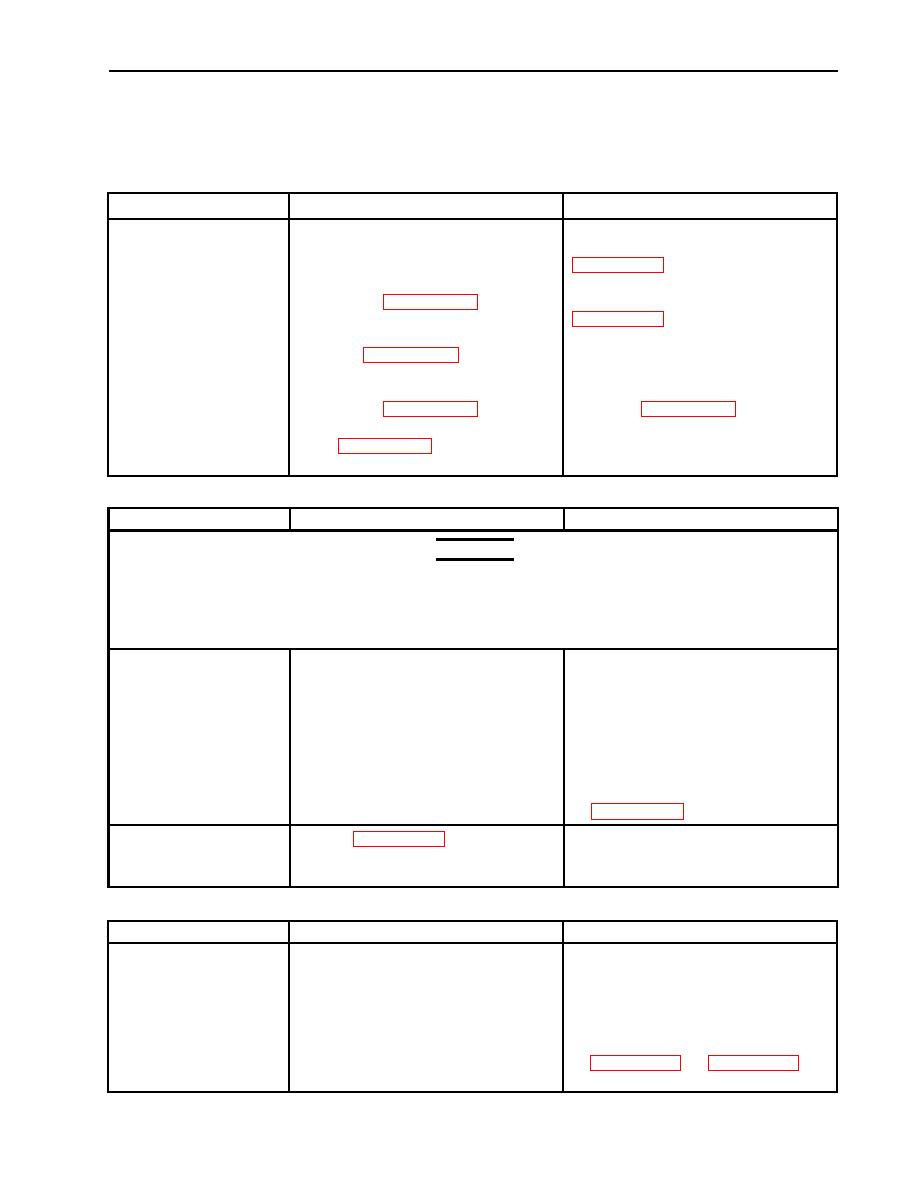

Table 2. Fuel System Troubleshooting Procedures (Contd).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. Check fuel injection pump return

If fuel return line is bent, kinked, or

4. FUEL INJECTORS

DELIVER EXCESS FUEL

line.

restricted, replace fuel return line

INTO ENGINE

2. Check fuel injection pump timing

If fuel injection timing to engine is

to engine (WP 0069 00).

incorrect, adjust to specifications

3. Check fuel injection internal

Replace defective components as

timing (WP 0008 00, table 2,

needed.

malfunction 2, step 3.

4. Check fuel injector nozzle

Replace fuel injection pump if

operation (WP 0008 00, table 2,

necessary (WP 0069 00).

malfunction 1, step 2.)

5. See WP 0008 00, table 1,

malfunction 3, step 3.

Table 3. Cooling System Troubleshooting Procedures.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

WARNING

Hot coolant is under pressure. Care should be used when removing radiator filler cap or inspecting

hot engine coolant leaks. Steam or hot coolant under pressure may cause severe injury to

personnel.

Wear hand protection at all times when working with heated parts. Failure to do so may result in

injury to personnel.

Flow test warm engine cooling

1. If flow test reading declines and

1. COOLANT LOSS

system (TM 750-254). Observe flow

there are no indications of

DURING NORMAL

test reading.

external leaks, coolant is leaking

OPERATION

internally into engine or

combustion chambers. Remove oil

dipstick and check engine oil for

presence of coolant.

2. If coolant is present on oil

dipstick, replace engine

Refer to WP 0006 00, table 4,

2. COOLANT

TEMPERATURE

malfunction 1.

EXCESSIVE

Table 4. Clutch System Troubleshooting Procedures.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. Check transmission condition.

1. If engine stalls, disconnect

1. VEHICLE WILL NOT

MOVE OR ENGINE

Place transfer case in neutral and

transmission to transfer case

STALLS WITH CLUTCH

transmission in first gear. Engage

propeller shaft for evidence of

ENGAGED

clutch and observe transmission

rotation.

to transfer propeller shaft for

2. Place transmission in neutral. If

evidence of rotation.

transmission will not turn, replace

repair transmission (WP 0450 00).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |