|

|||

|

|

|||

|

Page Title:

Table 19. Fuel Tank (M49A2C) Troubleshooting Procedures. |

|

||

| ||||||||||

|

|

TM 9-2320-361-24-1

0006 00

MECHANICAL SYSTEMS TROUBLESHOOTING - UNIT (Contd)

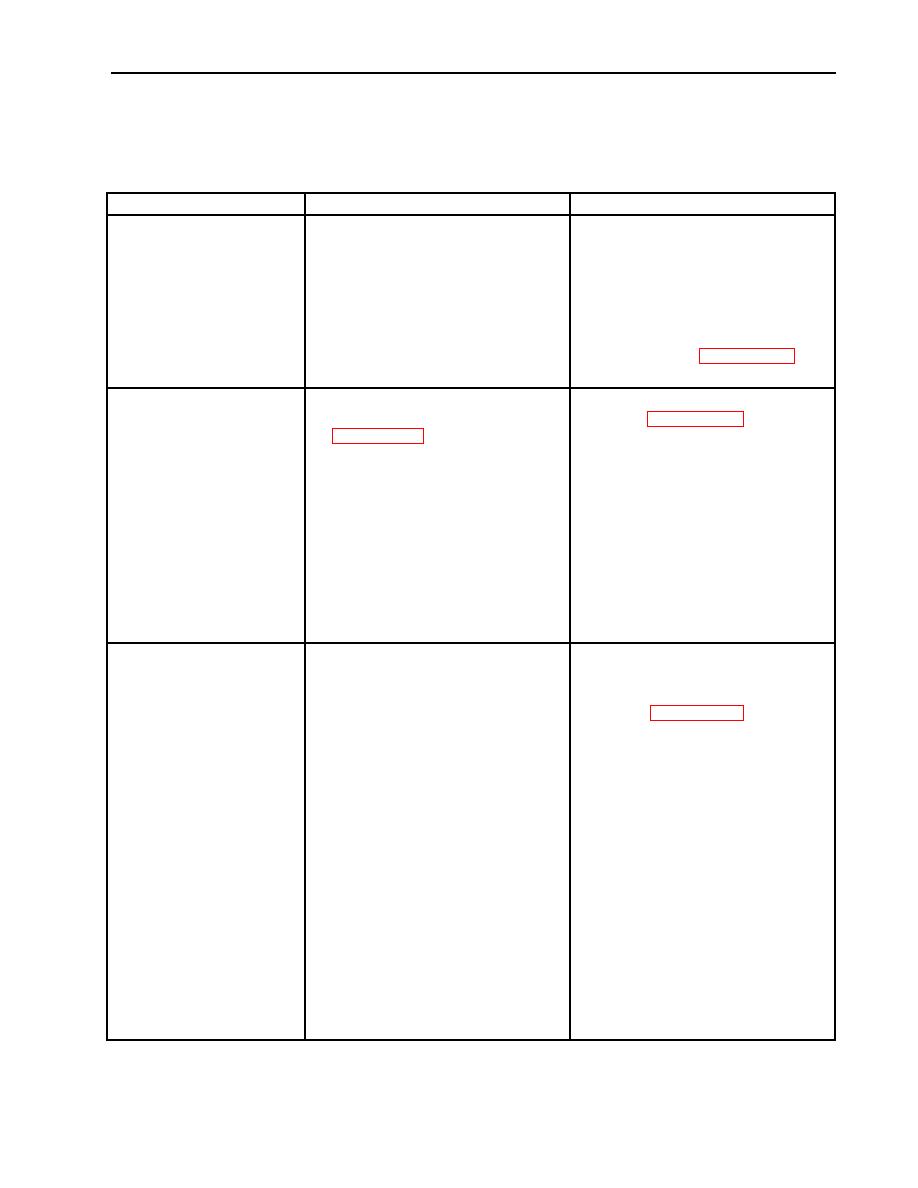

Table 19. Fuel Tank (M49A2C) Troubleshooting Procedures (Contd).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

4. Check operation of discharge

1. If control levers are not operating

2. DELIVERY PUMP

valve control levers.

properly, remove and inspect

DISPENSES FUEL SLOWLY

(WP 0264 00).

FROM BOTH TANKS

(Contd)

2. If control lever assembly

components are defective, replace

(WP 0264 00).

5. Check transfer case PTO

If transfer case PTO is not

operation.

operating, refer to WP 0006 00,

table 17, malfunction 4.

1. Check discharge control cables

Lubricate discharge control cable if

3. FUEL DOES NOT PUMP

for proper lubrication

necessary (WP 0020 00).

OR PUMPS SLOWLY

FROM SELECTED TANK,

AND FUEL DRAINS

2. Check discharge control cable for

If discharge control cable is broken

SLOWLY FROM SELECTED

breaks or kinks.

or kinked, replace (WP 0264 00).

TANK USING GRAVITY

3. Check discharge control cable for

If control cable needs adjustment,

PROCEDURES

proper adjustment.

remove slack in cable

(WP 0264 00).

4. Inspect discharge valve tubes for

If discharge valve tubes are bent,

bent, crushed, broken, or leaking

crushed, broken, or leaking, replace

tubes.

(WP 0266 00).

5. Inspect discharge valves for

If discharge valves are broken or

proper operation.

inoperative, replace (WP 0263 00).

1. Check delivery pump propeller

1. If shaft is broken, replace

4. FUEL TANK

shaft for broken universal joints

(WP 0292 00 or WP 0293 00).

COMPARTMENTS

or broken shaft.

CANNOT BE SUCTION

2. If universal joints are broken,

FILLED

replace (WP 0141 00).

2. Perform fuel filter separator

If fuel filter separator is restricted,

check (TM 9-2320-361-10).

replace (WP 0286 00).

3. Check delivery pump strainer for

1. If strainer is restricted, clean or

restrictions.

replace (WP 0284 00).

NOTE

If No. 2 diesel fuel is being used

and ambient air temperature is

32 F (0 C), the outlet pressure

may fall as low as 5 psi (34.5 kPa).

This could cause slow or no delivery

of fuel to delivery pump. Refer to

TM 9-2320-361-10 for fuel

separator inlet and outlet pressure

differences.

2. If fuel system is clean and

pressure is low, replace delivery

pump (WP 0280 00).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |