|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-209-34-2-3

d. Cleaning. There are no special cleaning procedures required. Refer to

cleaning procedures given in Part 1, para 1-3.

e.

Inspection and Repair.

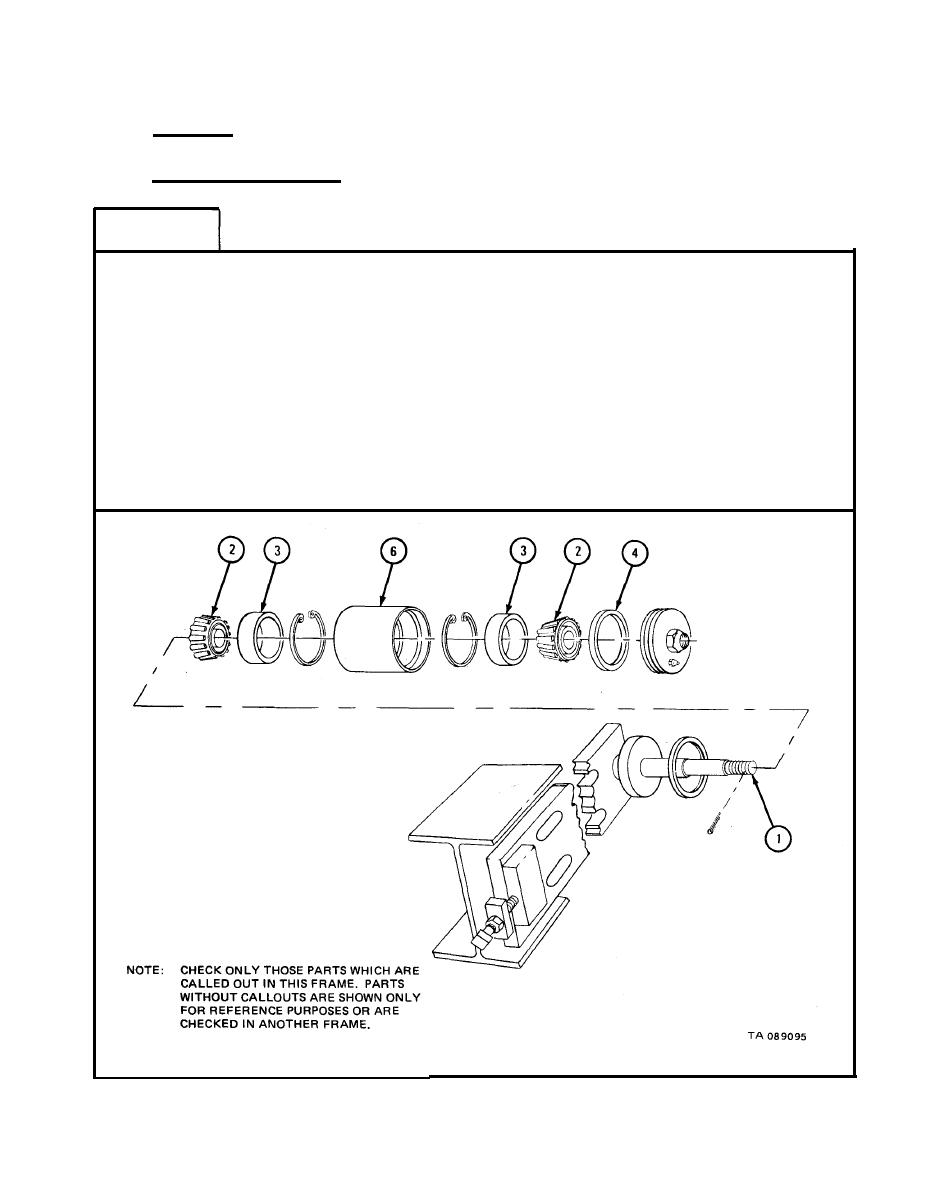

FRAME 1

1.

Check that idler pulley shaft (1) is not nicked, cracked, galled, scored or has

no damaged threads. If idler pulley shaft (1) is damaged, get a new one.

Put clean lubricating oil ICE, OE/HDO 10, MIL-L-2104 on two bearings (2)

2.

and turn by hand. The bearing must turn without binding. If bearing

assemblies are damaged, put in new ones.

3.

Check that two bearing cups (3) are not scored or pitted. If bearing cups are

damaged, get new ones.

4.

Check that bearing seals (4 and 5) are not worn, torn or burned. Be sure

seal makes good seal contact with pulley (6). If bearing seals are damaged,

get new ones.

G O TO FRAME 2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |