|

|||

|

|

|||

|

Page Title:

Inspection and Repair - continued |

|

||

| ||||||||||

|

|

TM 9-2320-209-34-2-3

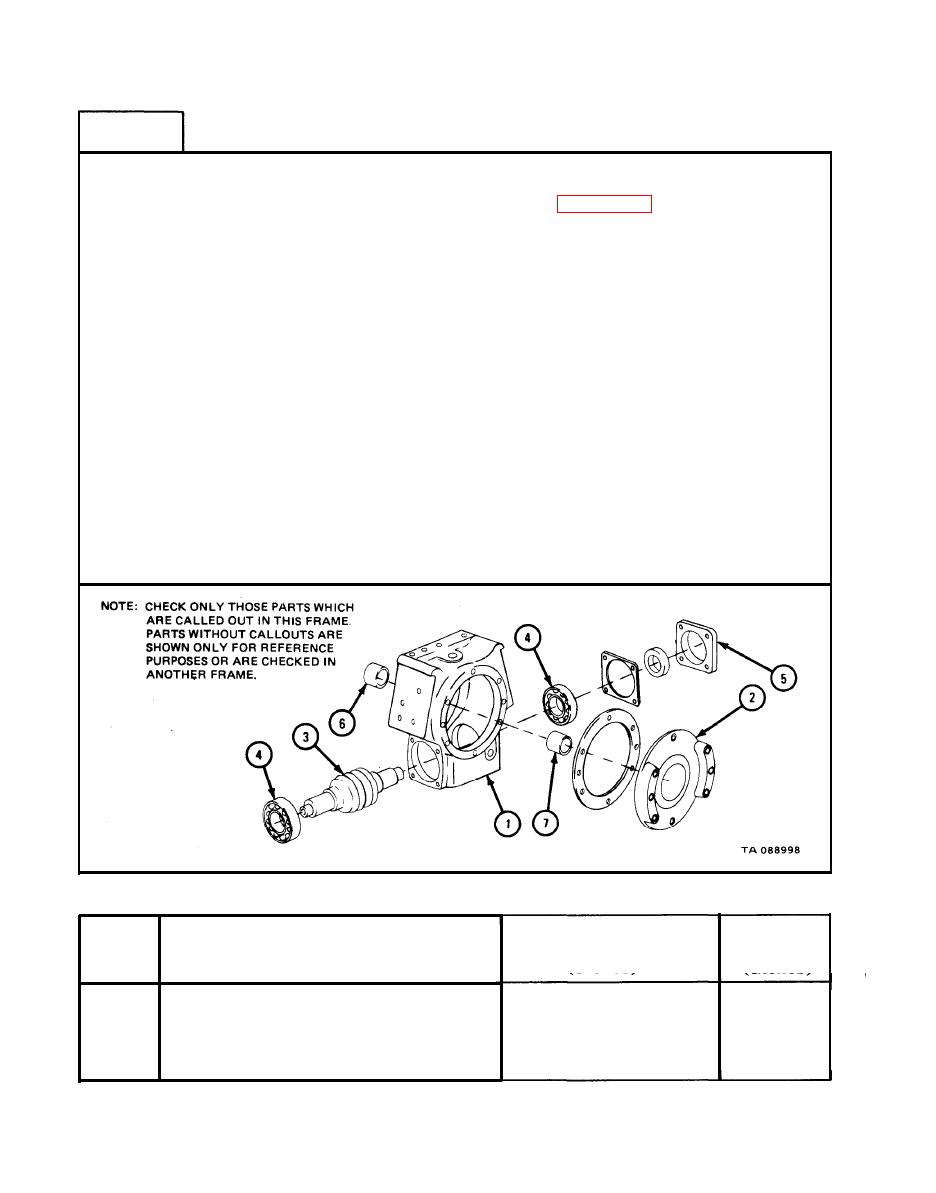

FRAME

4

NOTE

Readings must be within limits given in table 18-3. If

readings are not within given limits, throw away part

and get a new one.

1.

Check that gearcase (1) and gearcase cover (2) have no cracks, nicks, burrs

or damaged threads. Take off raised metal with a fine mill file, retap damaged

threads, and weld cracks. Refer to TM 9-237. If more repair is needed, get

a new part.

Check that drive worm (3) is not nicked, scored or damaged. If drive worm is

2.

damaged, get a new one.

Check that drive worm front and rear ball bearings (4) have no chips, rough-

3.

ness or flat spots. If ball bearings are damaged, get new ones. Put a coat of

engine lubricating oil on ball bearings to keep out dust and dirt.

Check that bearing cap (5) and its gasket surface are not cracked, nicked or

4.

burred. Take off raised metal with a fine mill file. If more repair is needed,

get a new part.

Measure inside diameter of gearcase bushing type bearing (6) and gearcase

5.

cover bushing type bearing (7).

GO TO FRAME 5

Table 18-3. Front Winch (Gearcase and Gearcase Cover Bearings) Wear Limits

Size and Fit

Wear Limit

of New Parts

Index

Item/Point of Measurement

Number

(inches)

(inches)

6

Gearcase bushing type bearing

1.8770 to 1.8800

1.8880

inside diameter

7

1.8770 to 1.8800

1.8880

Gearcase cover bushing type

bearing inside diameter

18-18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |