|

|||

|

|

|||

|

Page Title:

INTERMEDIATE CASE AND GEAR ASSEMBLY REMOVAL, REPAIR, REPLACEMENT AND ADJUSTMENT (TRUCK M764) - continued |

|

||

| ||||||||||

|

|

TM 9-2320-209-34-2-2

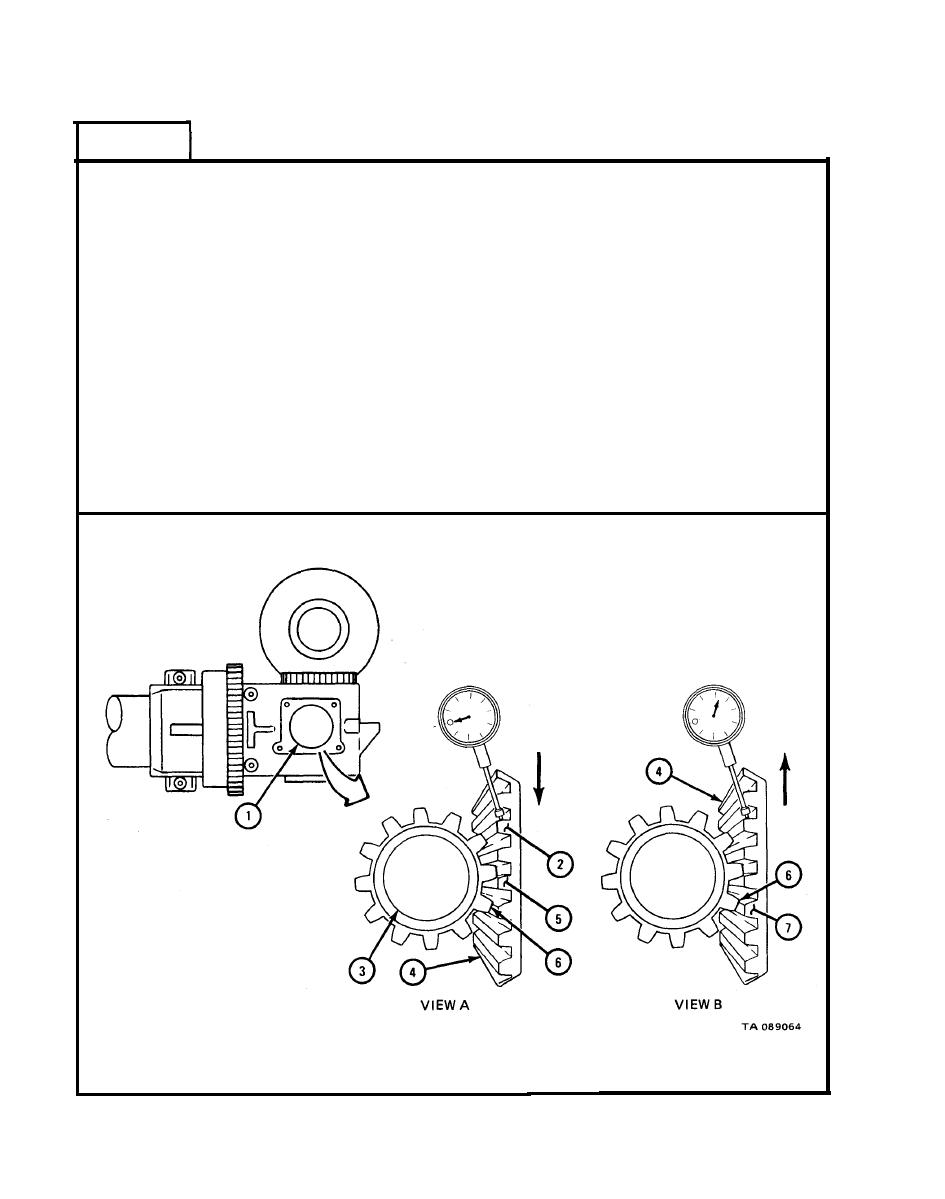

FRAME 3

Working through shaft hole in power leveler mounting flange (1), mount dial

1.

indicator on housing and set stem against side of reduction drive gear tooth

(2) as shown.

NOTE

When measuring backlash, make sure that first reduction

drive pinion (3) does not turn. If pinion turns, backlash

readings will be wrong.

2.

Turn drive gear (4) away from dial indicator until drive gear tooth (5) touches

pinion tooth (6) as shown in view A.

3.

Set dial indicator to read 0.

Turn drive gear (4) towards dial

indicator until drive gear tooth (7) touches

4.

-

shown in view B. Note reading on dial

either side o-f pinion tooth (6) as

indicator.

IF READING ON DIAL INDICATOR IS

NOT 0.006 TO 0.024 INCH, GO TO FRAME 4.

0.006 TO 0.024 INCH, END OF TASK

IF READING ON DIAL INDICATOR IS

17-552

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |