|

|||

|

|

|||

|

Page Title:

ELECTRICAL WIRING HARNESS REPAIR - continued |

|

||

| ||||||||||

|

|

TM 9-2320-386-24-1-1

0125 00

ELECTRICAL WIRING HARNESS REPAIR (Contd)

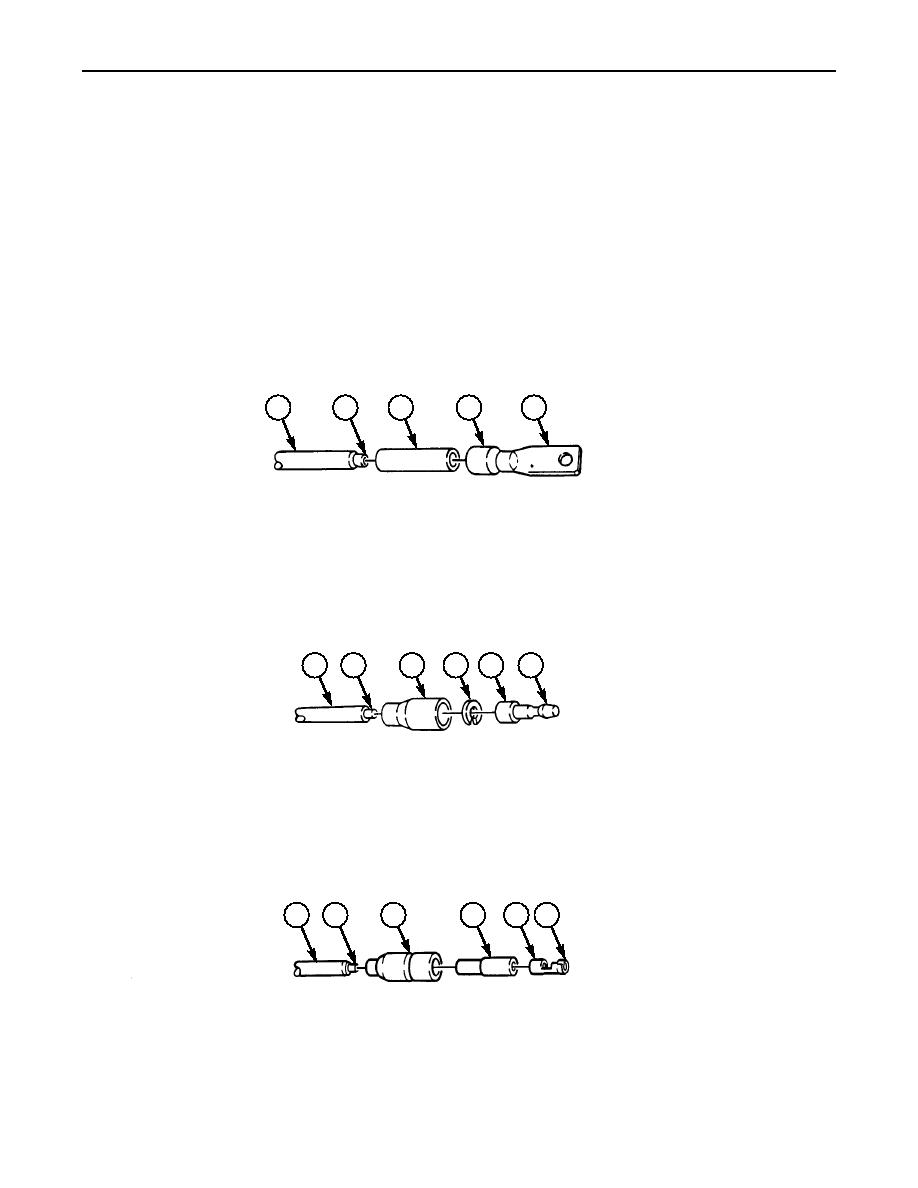

TERMINAL CABLE REPAIR

NOTE

Heat shrink insulation tubing is used on specific terminals of all

ESP vehicles. This tubing protects crimped connections at wiring

harness locations that have been designated as "vulnerable to

environmental conditions."

1.

Strip cable insulation tubing (1) from cable (2) to equal depth of terminal well (4).

2.

Slide insulation tubing (3) over cable insulation tubing (1).

3.

Insert cable (2) into terminal well (4) and crimp terminal well (4).

4.

Slide insulation tubing (3) over crimped end of terminal (5).

5.

Heat shrink insulation tubing (3) on insulation tubing (1) and terminal well (4).

1

2

3

4

5

LEAD REPAIR (MALE PLUG)

1.

Strip cable insulation tubing (1) from cable (2) to equal depth of terminal well (4).

2.

Slide shell (6) over cable (2) and cable insulation tubing (1).

3.

Insert cable (2) into terminal well (4) and crimp terminal well (4).

4.

Place slotted washer (7) over crimped junction at terminal (8).

5.

Slide shell (6) and terminal (8) over slotted washer (7).

1

2

6

7

4

8

LEAD REPAIR (FEMALE PLUG)

1.

Strip cable insulation (1) from cable (2) to equal depth of terminal well (4).

2.

Slide shell (9) and sleeve (10) over cable (2) and cable insulator (1).

3.

Position cable (2) into terminal well (4) and crimp terminal well (4).

4.

Slide sleeve (10) and shell (9) over terminal (11).

1

2

9

10

4

11

0125 00-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |