|

|||

|

|

|||

|

Page Title:

Table 1. Indicator, Gauges, and Warning System Troubleshooting - continued |

|

||

| ||||||||||

|

|

TM 9-2320-361-24-1

0014 00

INDICATORS, GAUGES, AND WARNING SYSTEM TROUBLESHOOTING (Contd)

Table 1. Indicator, Gauges, and Warning System Troubleshooting (Contd).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

NOTE

5. VOLTMETER

INOPERATIVE

If STE/ICE-R is available, perform

NG 31 gauge test (WP 0018 00).

Test 1. Test voltmeter.

1. Turn power accessory switch

to ON position. Do not start

engine.

2. Voltmeter should rest between

lower edge of green area and

upper edge of yellow area on

gauge (24 volts).

3. Start engine (TM 9-2320-361-10)

and observe voltmeter on

instrument cluster.

If voltmeter does not perform as

4. Voltmeter should rise as

specified in steps 2 and 4, stop engine

engine speeds up and stop

and go to test 2.

over white dot in green area

(approximately 28 VDC).

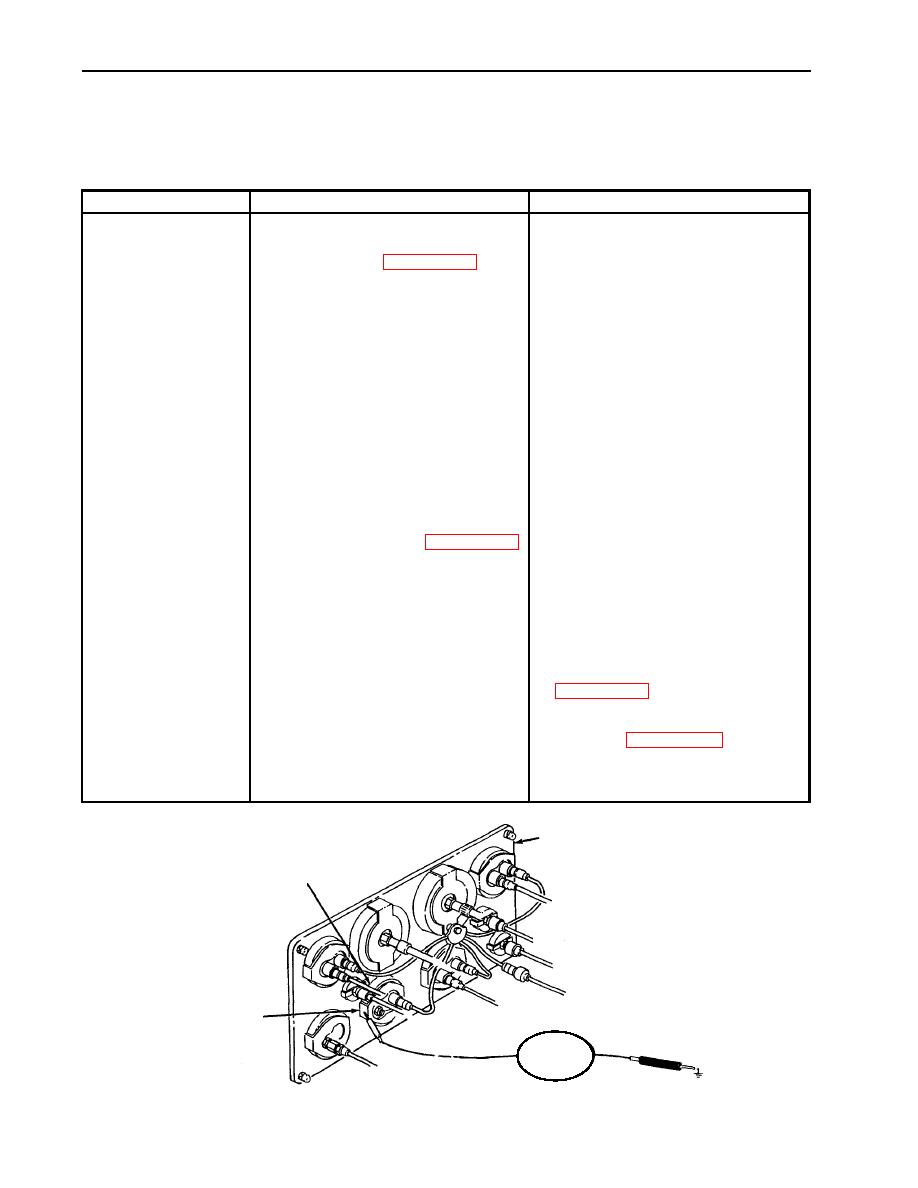

Test 2. Test battery voltage to

alternator. Go to WP 0012 00,

table 3, malfunction 1, test 3.

Check frame ground to multimeter.

1. Set multimeter to RX 1 scale.

2. Connect negative lead to

panel ground on instrument

panel.

1. If continuity is present, reinstall

3. Touch positive lead to

instrument panel cluster

voltmeter bracket. Continuity

should be present. Ensure

instrument panel cluster.

instrument panel is grounded.

2. If continuity is not present, remove

alternator (WP 0085 00) and check

for corrosion around alternator

body.

INSTRUMENT

PANEL

BRACKET

TEST 2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |