|

|||

|

|

|||

|

Page Title:

Table 3. Compressed Air Troubleshooting Procedures - continued |

|

||

| ||||||||||

|

|

TM 9-2320-361-24-1

0010 00

COMPRESSED AIR AND BRAKE SYSTEM TROUBLESHOOTING (Contd)

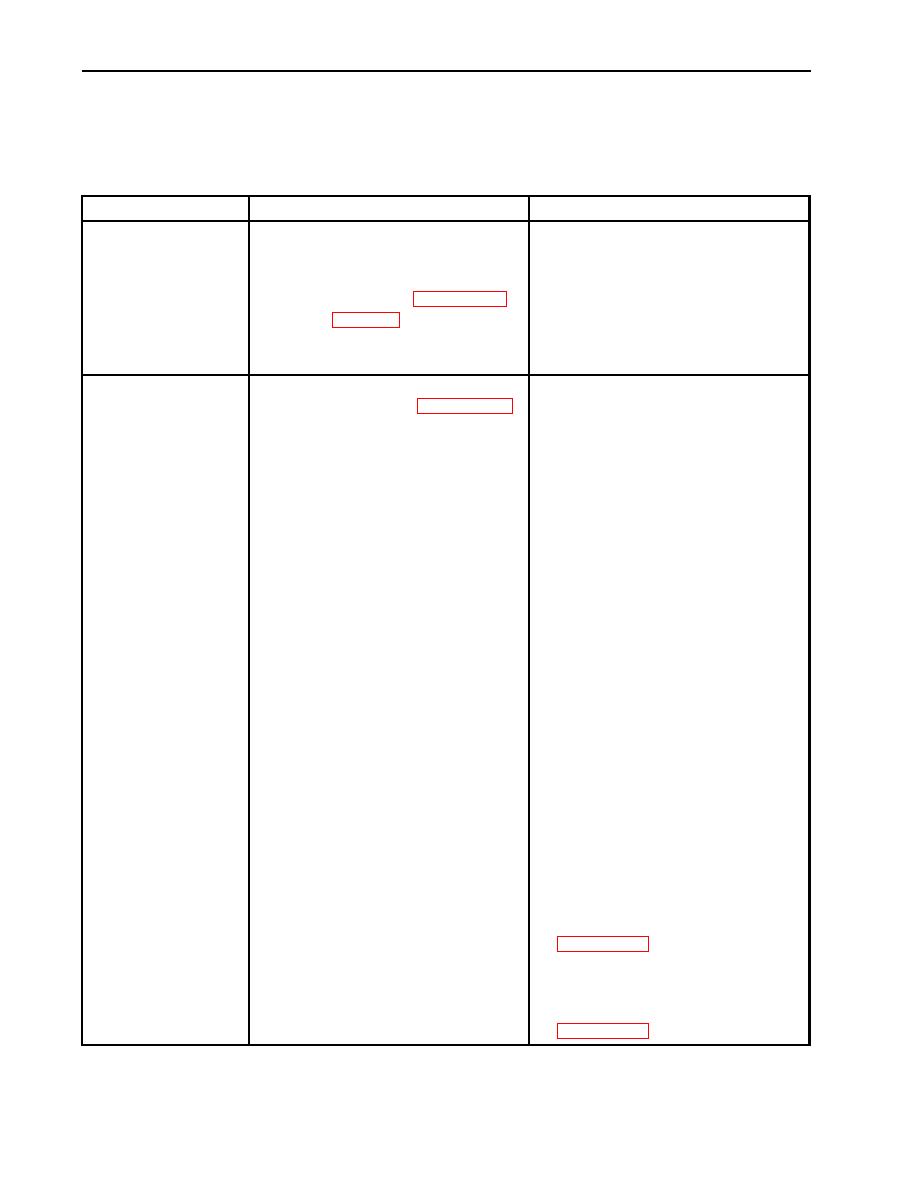

Table 3. Compressed Air Troubleshooting Procedures (Contd).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

2. AIR PRESSURE DOES 1. Check for compressed air leaks.

If leak is found, repair or replace

compressed air lines or fittings

NOT BUILD UP

(TM 9-243).

TO NORMAL

OPERATING

2. Adjust air governor (WP 0183 00).

PRESSURE (ABOVE

TO GAUGE

malfunction 1, test 2.

1. Check for air loss through

3. AIR PRESSURE

accessories. (Refer to WP 0010 00,

EXCEEDS MAXIMUM

table 4, malfunctions 1, 2, and 3).

(GAUGE READS

OVER 120 PSI) AND

2. Check governor signal line (4) for

1. If governor signal line (4) is

SAFETY VALVE

bends, or leaks.

crimped, bent, or leaking, repair or

OPENS TO RELEASE

replace governor signal line (4)

AIR PRESSURE

(TM 9-243).

2. If no restrictions are apparent,

proceed to test 1.

Test 1. Check governor signal line (4)

pressure.

1. Stop engine and open all drain

valves (TM 9-2320-361-10)

until all air pressure is

released from brake system.

2. Disconnect governor signal

line (4) from adapter (3).

3. Remove adapter (3) from air

governor (2).

4. Install tee (5) on air

governor (2).

5. Connect test gauge (1) and

governor signal line (4) to

tee (5).

6. Direct assistant to start

engine (TM 9-2320-361-10)

and allow air supply to build

up to normal operating

pressure.

7. Compare air pressure reading 1. If test gauge (1) reading is below

indicated on test gauge (1) to

85 psi (586 kPa), adjust governor

air pressure indicated on

instrument panel gauge.

2. If governor adjustment does not

increase governor signal line (4)

pressure above 85 psi (586 kPa) on

test gauge (1), replace air governor

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |