|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-209-34-2-3

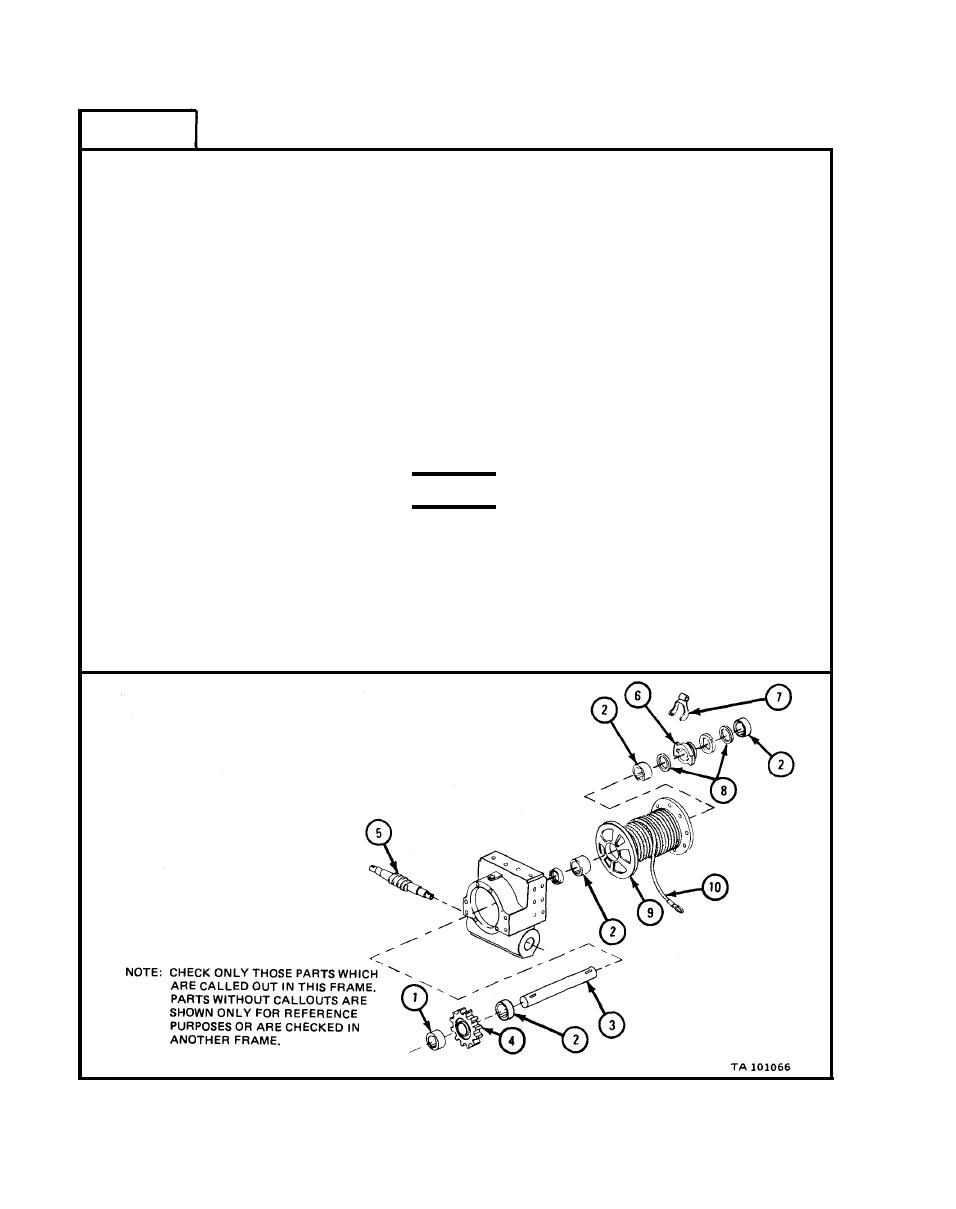

FRAME 2

1.

Check that bores of sleeve bearings (1 and 2) have no burrs, nicks, scoring

or roughness. Take off raised metal, nicks, scoring, and roughness with a

honing stone, and polish with crocus cloth.

2.

Using magnifying glass, check that drum shaft (3) has no cracks. If drum

shaft is cracked, get a new one.

3.

Check that drum shaft (3) is not scored or worn. If drum shaft is scored or

worn, get a new one.

4.

Check that teeth of gears (4 and 5) are not broken, chipped or scored. If

gear teeth are damaged, get a new gear.

5.

Check that sliding clutch (6), shifter yoke (7), and two thrust rings (8) are

not worn. If parts are worn, get new ones.

Check that flange on drum (9) is not chipped or worn where drag brake

6.

touches it. If flange is damaged, get a new drum. Check that all oil passages

are open.

WARNING

Always wear leather gloves when handling winch cable.

Never let cable run through hands. Broken or rusty

wires can cause serious injury to personnel.

Unwind cable (10). Check that cable has no broken or frayed strands. If

7.

cable is damaged, take it off drum and put on a new one. Refer to

TM 9-2320-209-20.

GO TO FRAME 3

18-48

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |