|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM

9-2320-209-20-3-2

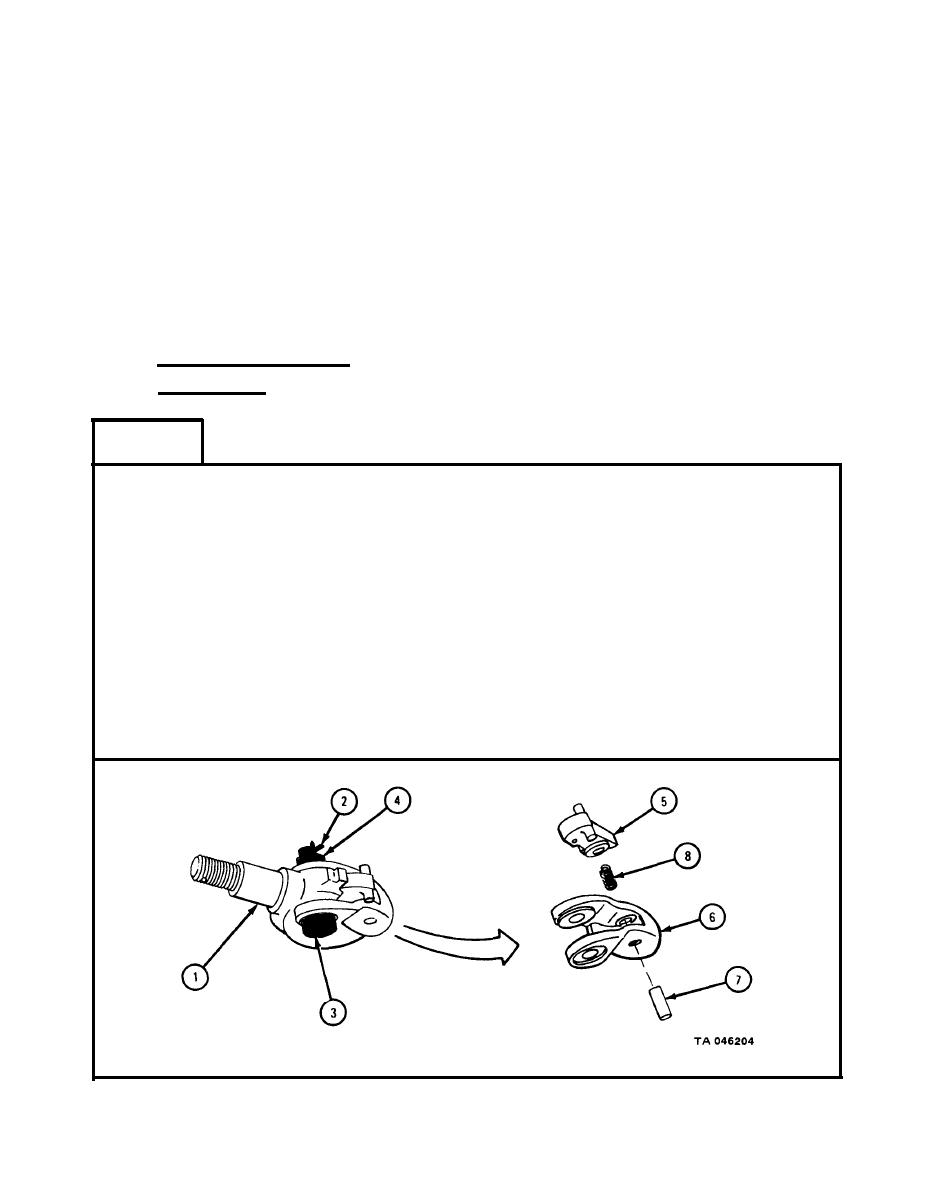

PINTLE

HOOK

REPAIR.

Center

punch

TOOLS:

Pliers

Anvil

1

1/2-inch

wrench

(2)

Vise

Drift

punch

Hammer

Solvent,

dry

cleaning,

type

II

(SD-2),

SUPPLIES:

Fed.

Spec

P-D-680

Artillery

and

automotive

grease,

type

GAA,

MIL-G-10924

PERSONNEL:

Two

Truck

parked,

engine

off,

handbrake

set.

EQUIPMENT

CONDITION:

16-5.

Take

pintle

hook

off

truck.

Refer

to

para

a.

Preliminary

Procedure.

b.

Disassembly.

FRAME

1

1.

Put

pintle

hook

(1)

in

vise.

2.

Using

pliers,

take

out

cotter

pin

(2).

hold

bolt

(3)

and

unscrew

and

take

off

nut

(4).

Take

out

3.

Using

wrenches,

bolt.

Take

pintle

hook

(1)

out

of

vise

and

put

latch

(5)

into

vise.

4.

5.

Using

hammer,

tap

off

lock

(6)

from

pintle

hook

(1).

6.

Using

hammer

and

drift

punch,

drive

out

pin

(7).

Spring

(8)

will

stay

on

latch.

Take

off

spring.

Take

lock

(6)

off

latch

(5).

7.

8.

Take

latch

(5)

out

of

vise.

IF

WORKING

ON

PINTLE

WITH

TEFLON

BUSHINGS,

GO

TO

FRAME

2.

IF

WORKING

ON

PINTLE

WITH

GREASE

FITTING,

END

OF

TASK

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |