|

|||

|

|

|||

|

Page Title:

TRANSMISSION INSTALLATION - continued |

|

||

| ||||||||||

|

|

TM 9-2320-361-24-1

0132 00

TRANSMISSION INSTALLATION (Contd)

INSTALLATION

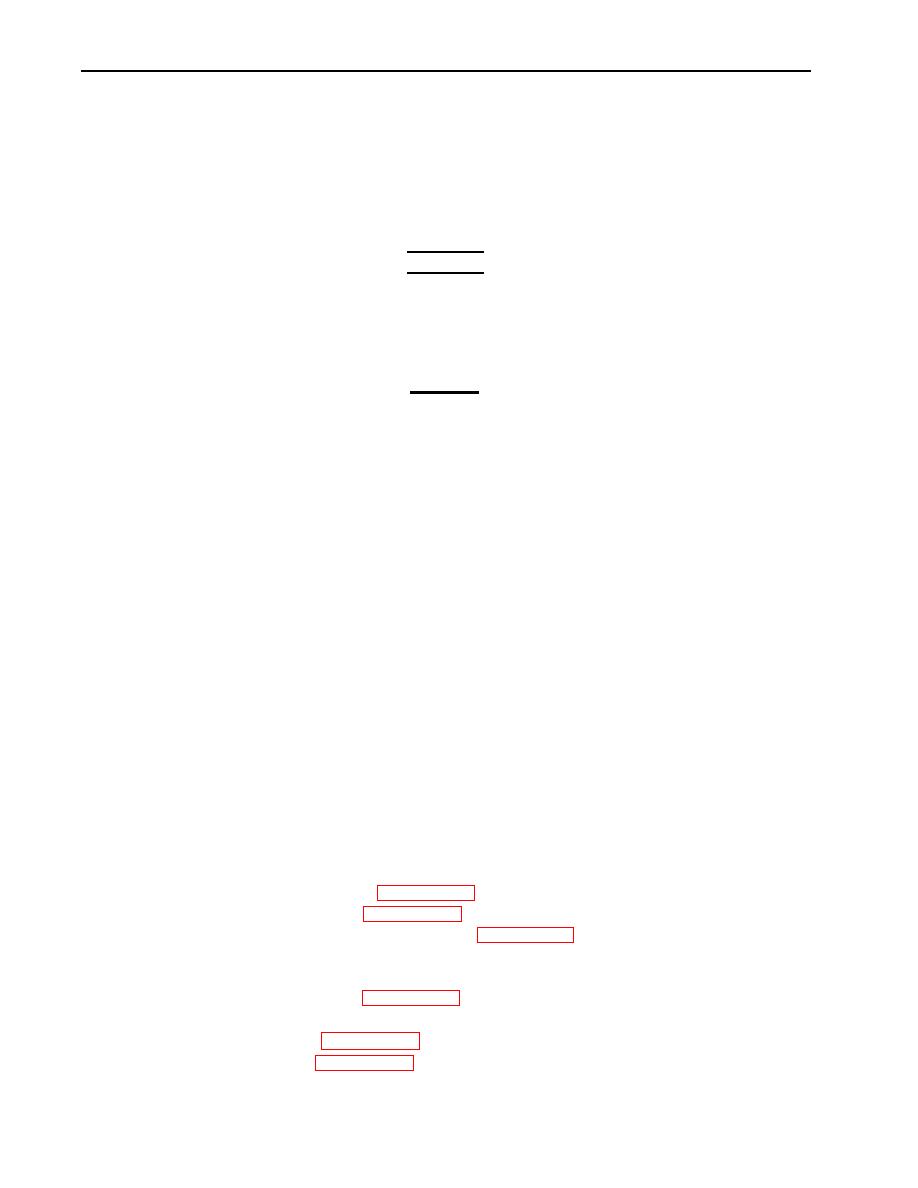

1. Install utility chains on transmission (6) with four washers (4) and screws (3).

2. Attach sling to utility chains. Attach lifting device to sling.

3. Position transmission (6) under vehicle and raise transmission (6).

WARNING

All personnel must stand clear during lifting operations. A

swinging or shifting load may cause injury to personnel.

Lifting device must have a weight capacity greater than the

weight of the transmission to prevent damage to equipment

and injury to personnel.

CAUTION

Ensure transmission is aligned with clutch and pilot bearing.

Failure to do so may result in damage to equipment.

4.

Install new gasket (2) and transmission (6) on flywheel housing (1) with eleven new screw

assembled lockwashers (11). Tighten screw-assembled lockwashers (11) 2326 lb-ft (3135 Nm).

5.

Install new lockwasher (17) and ground strap (16) on transmission (6) with new screw-assembled

lockwasher (11). Tighten screw-assembled lockwasher (11) 2326 lb-ft (3135 Nm).

6.

Remove lifting device from sling. Remove sling from utility chains.

7.

Remove four screws (3), washers (4), and utility chains from transmission (6).

8.

Install four new screw-assembled lockwashers (5) on transmission (6). Tighten screw-assembled

lockwashers (5) 2532 lb-ft (3443 Nm).

9.

Align mark on lever (14) with shaft (12) and install lever (14) on shaft (12) with screw (15) and

new locknut (13).

NOTE

If mark does not exist on shaft or lever, position lever on spline

to rear of shaft centerline.

10.

Push lower end of lever (14) forward until resistance is felt. Measure distance from center of hole on

lever (14) to flange of transmission (6). Measurement should be 3.25 in. (8.26 cm). Rotate lever (14)

one spline at a time if necessary to obtain 3.25 in. (8.26 cm) measurement. Tighten locknut (13).

NOTE

Perform step 11 if PTO is installed.

11.

Attach power takeoff shift lever (8) on PTO arm (10) and push pin (7) in clevis (9) until head of

pin (7) seats against clevis (9).

12.

Install rod (23) on clutch shaft lever (18) with screw (22) and new locknut (21).

13.

Install clevis (25) on lever (14).

14.

Push pin (24) in clevis (25) until head of pin (24) seats against clevis (25).

15.

Install clutch return spring (19) on clutch shaft lever (18) and frame (20).

16.

Fill transmission to proper fluid level (WP 0020 00).

17.

Install intermediate propeller shaft (WP 0140 00).

18.

Install transfer case to transmission propeller shaft (WP 0139 00).

19.

Install power takeoff propeller shaft (if removed) (WP 0346 00).

20.

Install cab tunnels (WP 0230 00).

21.

Install transmission gearshift lever (WP 0130 00).

22.

Install cab top (if removed) (TM 9-2320-361-10).

23.

Connect battery ground cable (WP 0126 00).

24.

Adjust clutch pedal free play (WP 0047 00).

25.

Release parking brake and remove wheel chocks (TM 9-2320-361-10).

0132 00-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |