|

|||

|

|

|||

|

Page Title:

MECHANICAL SYSTEMS TROUBLESHOOTING - DIRECT SUPPORT |

|

||

| ||||||||||

|

|

TM 9-2320-361-24-1

FIELD TROUBLESHOOTING

2-1/2 TON, 6X6, M44A2 SERIES TRUCKS (MULTIFUEL)

MECHANICAL SYSTEMS TROUBLESHOOTING - DIRECT SUPPORT

NOTE

Test run engine after each completed action.

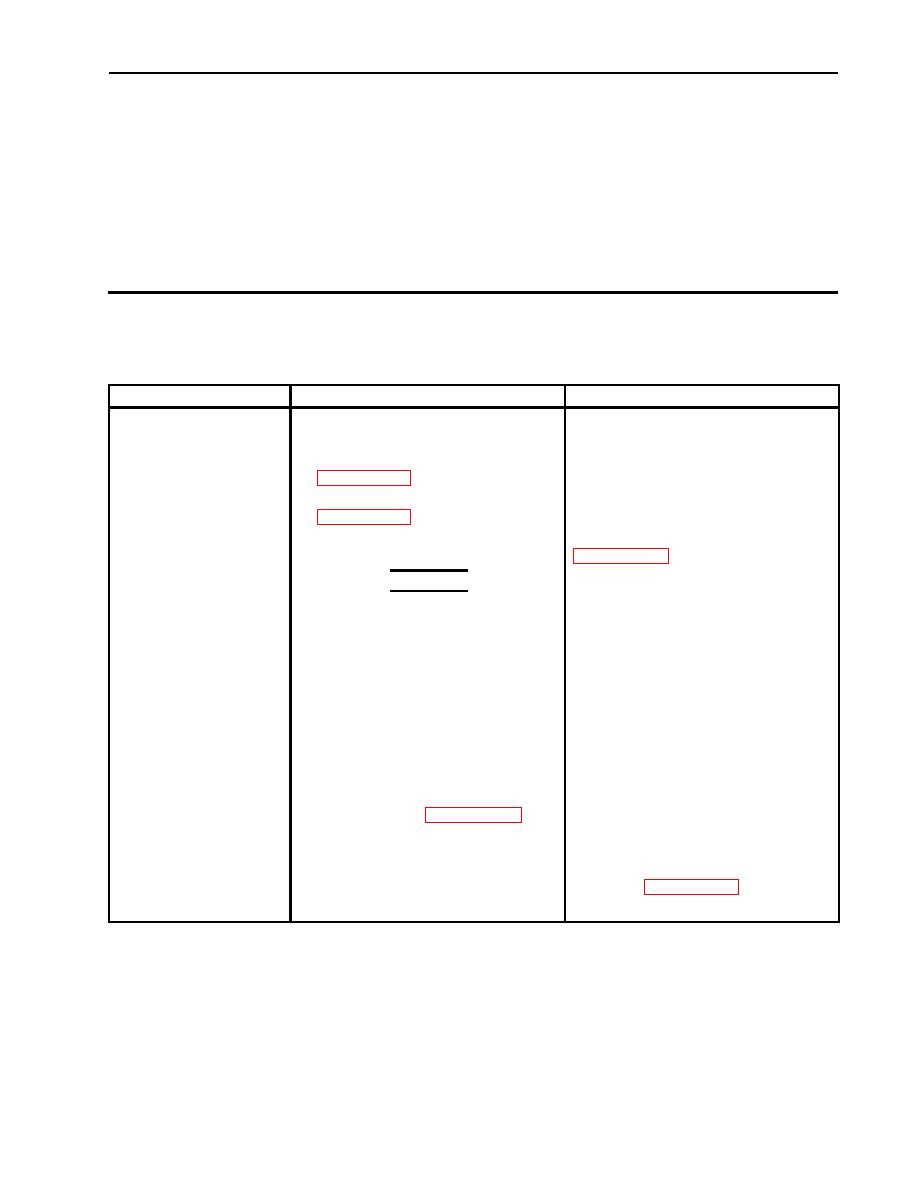

Table 1. Engine Troubleshooting Procedures.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Inspect fuel injection pump for

1. ENGINE WILL NOT

seizure.

CRANK

1. Remove drive gear access cover

2. Remove injection pump drive gear

If shaft will not rotate, replace

3. Manually turn injection pump

shaft at center hub screw.

pump (WP 0446 00).

WARNING

Ensure fuel shutoff valve is off

and remove throttle cable before

cranking engine. Failure to do so

may result in injury to personnel.

All personnel must stand away

from engine during crank test.

Wear eye protection during crank

test. Failure to stand clear and

wear eye protection may cause

injury or death to personnel.

4. Check engine cylinders for fluid

1. If crankshaft turns freely, identify

locked pistons. Remove all fuel

any fluid levels expelled from

injector nozzles (WP 0067 00).

cylinders. If fluid sample is

Crank engine with starter.

identified as coolant, proceed to

step 11.

2. If fluid sample is identified as fuel,

refer to WP 0008 00, table 2,

malfunction 4.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |