|

|||

|

|

|||

|

Page Title:

SNATCH SHEAVE ASSEMBLY REPAIR (TRUCK M764) - continued |

|

||

| ||||||||||

|

|

TM 9-2320-209-34-2-2

d.

Inspection and Repair.

FRAME 1

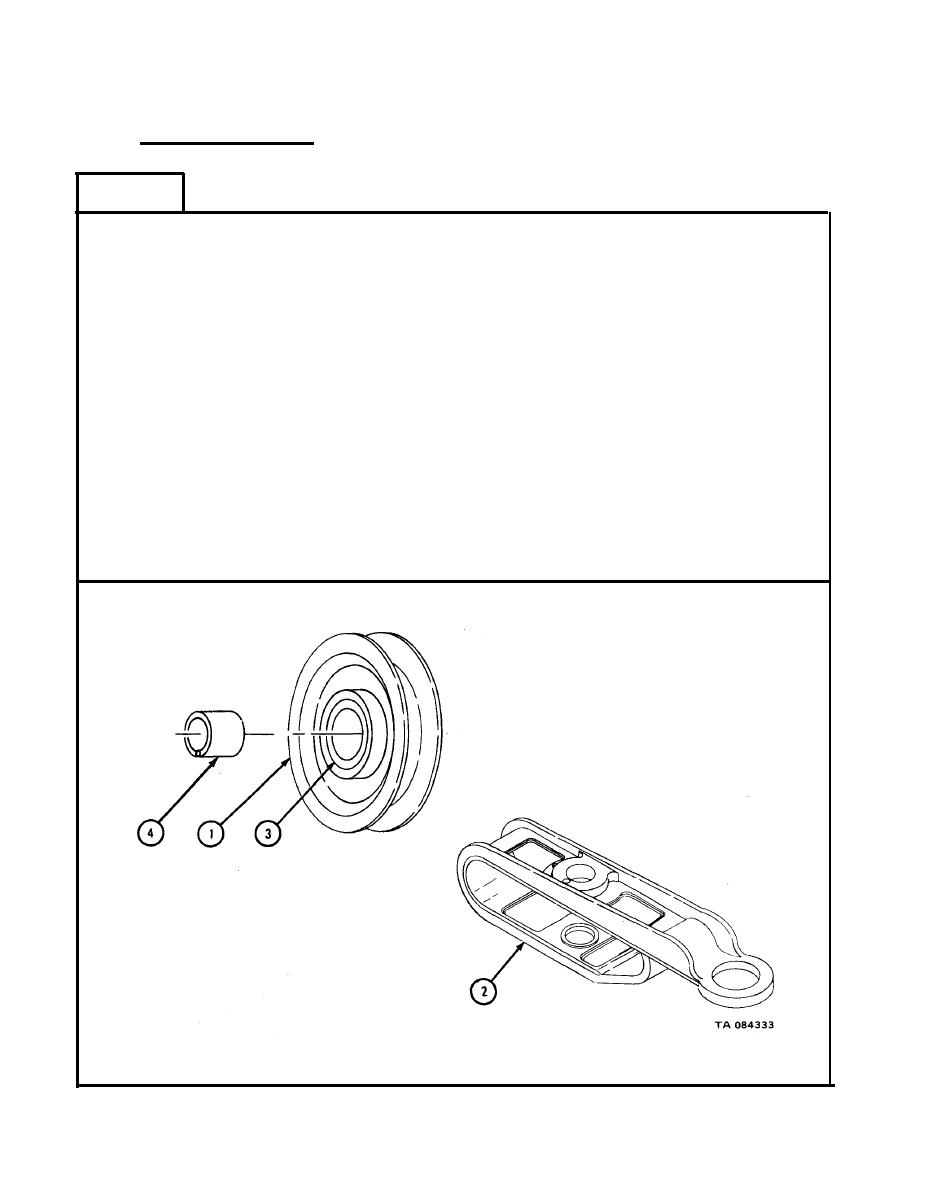

Check that sheave pulley assembly (1) and sheave housing (2) have no cracks

1.

or other damage. Fix cracks by welding. Refer to TM 9-237. If parts need

more repair, throw them away and get new ones.

2.

Check that sleeve bearing (3) has no nicks, cracks or burrs. Take off raised

metal with a fine mill file. If sleeve bearing needs more repair, press it out

and press in a new sleeve bearing.

3.

Check that inside diameter of sleeve bearing (3) is not more than 1.770 inches.

If inside diameter is more than limit given, out bearing and press in a new one.

4.

Check that bearing spacer (4) has no nicks, cracks or burrs. Take off raised

metal with fine mill file. If more repair is needed, get a new bearing spacer.

5.

Check that outside diameter of bearing spacer (4) is not less than 1.735 inches.

If outside diameter is less than limit given, get a new bearing spacer.

6.

If sleeve bearing (3) or bearing spacer (4) were changed, make sure that bearing

spacer fits in bearing. If bearing spacer does not fit, ream or burnish inside of

sleeve bearing (3) so bearing spacer fits inside.

END OF TASK

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |