|

|||

|

|

|||

|

Page Title:

FUEL INJECTOR TIMING MAINTENANCE - continued |

|

||

| ||||||||||

|

|

TM 9-2320-386-24-1-2

0322 00

FUEL INJECTOR TIMING MAINTENANCE (Contd)

NOTE

Do not pull on or touch vertical dial indicator when removing

holding fixture. If dial indicator is moved, the double zero on the

vertical dial indicator must be reset.

18.

Remove holding fixture with dial indicators from injector by pressing top ball on pivot arm of

holding fixture fully and pulling holding fixture straight up.

19.

Repeat steps 9 through 18 for two remaining injectors.

20.

Remove timing bolt from timing hole (2) on flexplate housing (1).

NOTE

When turning crankshaft, use the four large screws on front of

crankshaft. Do not use the eight small screws on front of

crankshaft pulley.

21.

Rotate crankshaft clockwise 360 degrees until timing bolt engages non-threaded hole in flywheel.

NOTE

No. 1 piston is on compression stroke if intake and exhaust valves

are closed and rocker arms can be moved by hand.

No. 1 piston is on exhaust stroke if intake and exhaust valves are

open and rocker arms cannot be moved by hand.

22.

Position No. 1 piston at TC and make identification for the correct stroke (compression or exhaust).

Refer to table 2 for correct injector sequence.

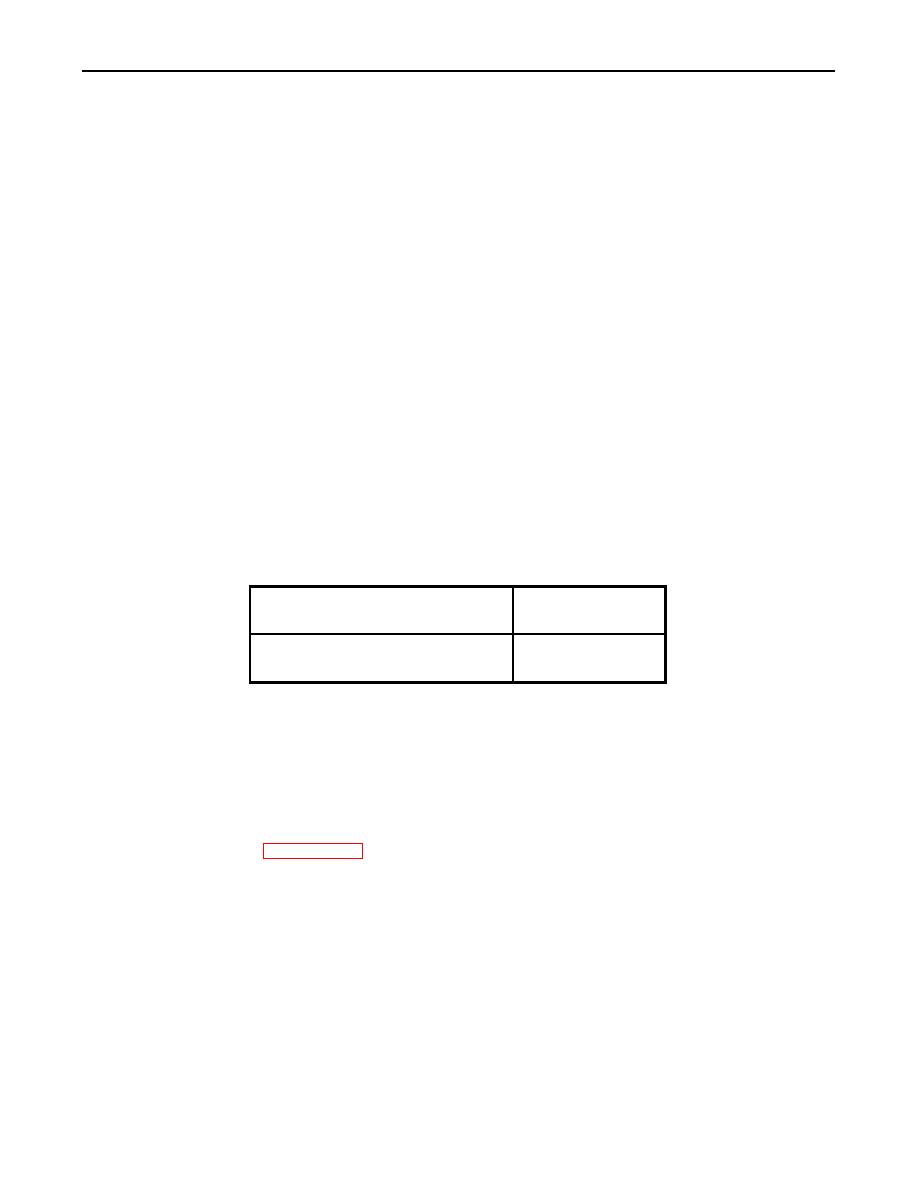

Table 2. Crankshaft Positions for Fuel Timing.

Check/adjust with No. 1

Injectors 3-5-6

piston on TC compression stroke

Check/adjust with No. 1

Injectors 1-2-4

piston on TC exhaust stroke

NOTE

Set timing for No. 1 injector last. This will be correct position to

check and adjust fuel setting later.

23.

Repeat steps 9 through 18 until all the injectors are checked, according to the correct stroke

(compression or exhaust). Refer to table 2 for correct injector sequence.

24.

Remove timing bolt from timing hole (2) on flexplate housing (1).

25.

Install new O-ring (3) and plug (4) in timing hole (2) on flexplate housing (1).

26.

Adjust fuel setting (WP 0323 00).

0322 00-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |