|

|||

|

|

|||

|

Page Title:

FUEL INJECTOR TIMING MAINTENANCE - continued |

|

||

| ||||||||||

|

|

TM 9-2320-386-24-1-2

0322 00

FUEL INJECTOR TIMING MAINTENANCE (Contd)

7.

Clean top surfaces of injector tappets (1) with lint-free cloth.

NOTE

No. 1 piston is on compression stroke if intake and exhaust valves

are closed and rocker arms can be moved by hand.

No. 1 piston is on exhaust stroke if intake and exhaust valves are

open and rocker arms cannot be moved by hand.

Set timing for No. 1 injector last. This will be correct position to

check and adjust fuel setting later.

8.

Position No. 1 piston at TC and make identification for the correct stroke (compression or exhaust).

Refer to table 1 for correct injector sequence.

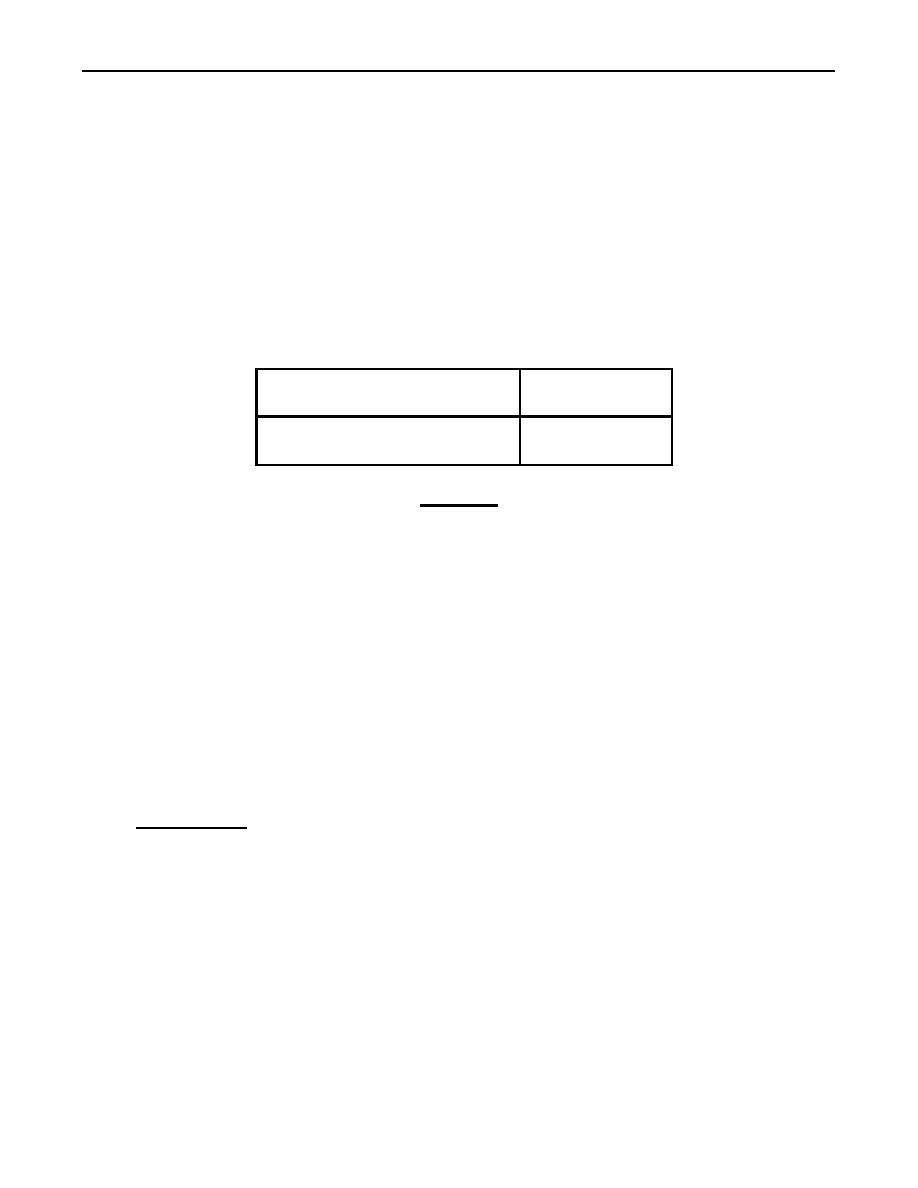

Table 1. Crankshaft Positions for Fuel Timing.

Check/adjust with No. 1

Injectors 3-5-6

piston on TC compression stroke

Check/adjust with No. 1

Injectors 1-2-4

piston on TC exhaust stroke

9.

Press top ball on pivot arm of holding fixture fully and hold.

CAUTION

Bottom contact point on pivot arm of holding fixture must clear

end of rack bar when inserted into engine. Failure to do so will

cause damage to equipment and result in an inaccurate reading.

10.

While keeping top ball on pivot arm pressed, insert holding fixture with dial indicators at injector

to be timed so stabilizing blade seats against intake valve spring (5), and spring clip seats against

inside of air intake manifold (6).

11.

Push down on holding fixture and listen for a "snap" sound to ensure holding fixture is seated

against injector base.

12.

Release top ball on pivot arm of holding fixture. Ensure pivot arm contacts face of rack bar (4) and

indicator contact point contacts injector tappet (1).

NOTE

Refer to valve cover information plate for fuel timing dimension.

13.

Determine the fuel timing dimension of engine. The set block for calibration measures 62.0 mm. To

determine what the vertical dial indicator should read, subtract 62.0 mm from the fuel timing

dimension on valve cover.

xx.xx mm

Fuel timing dimension on valve cover

62.00 mm

Set block for calibration

=

xx.xx mm

Vertical dial indicator reading

14.

Ensure vertical dial indicator matches the answer from step 13 0.05 mm.

a. If vertical dial indicator does match the answer from step 13 0.05 mm, timing is correct and no

adjustment is necessary. Go to step 18.

b. If vertical dial indicator does not match the answer from step 13 0.05 mm, timing is incorrect

and adjustment is necessary. Go to step 15.

15.

Loosen jamnut (3) on push rod adjustment screw (2).

16.

Turn push rod adjustment screw (2) until reading on vertical dial indicator matches answer from

step 13 0.05 mm.

NOTE

Thread pull can cause adjustment to change when jamnut is

tightened, and readjustment may be necessary.

Tighten jamnut (3) on push rod adjustment screw (2) 13-23 lb-ft (18-31 Nm).

17.

0322 00-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |