|

|||

|

|

|||

|

Page Title:

INTAKE AND EXHAUST VALVE CLEARANCE CHECK AND ADJUSTMENT - continued |

|

||

| ||||||||||

|

|

TM 9-2320-386-24-1-2

0311 00

INTAKE AND EXHAUST VALVE CLEARANCE CHECK AND ADJUSTMENT (Contd)

5.

Remove timing bolt from timing hole (2) on flexplate housing (1).

NOTE

When turning the crankshaft, use the four large screws on the

front of the crankshaft. Do not use the eight small screws on the

front of the crankshaft pulley.

No. 1 piston is on compression stroke if intake and exhaust valves

are closed and rocker arms can be moved by hand.

No. 1 piston is on exhaust stroke if intake and exhaust valves are

open and rocker arms cannot be moved by hand.

6.

Rotate crankshaft clockwise 360 degrees to next stroke position until timing bolt engages non-

threaded hole in flywheel.

7.

Repeat step 4 to check valve clearance.

8.

If adjustment is not required, perform Fuel Injector Timing Adjustment (WP 0322 00).

ADJUSTMENT

NOTE

Before performing intake and exhaust valve adjustment, ensure

No. 1 piston is at top center (TC) and correct stroke is identified.

Refer to table 1, Crankshaft Positions for Valve Clearance Setting.

1.

Using soft hammer, tap adjusting screw (5) of rocker arm (4).

2.

Loosen jamnut (6) and insert feeler gauge between rocker arm (4) and valve (3).

3.

Adjust intake and exhaust valve clearance by turning adjusting screw (5) counterclockwise to

increase valve clearance or clockwise to decrease valve clearance. Refer to table 2, Valve Clearance

Setting, for proper valve clearance setting.

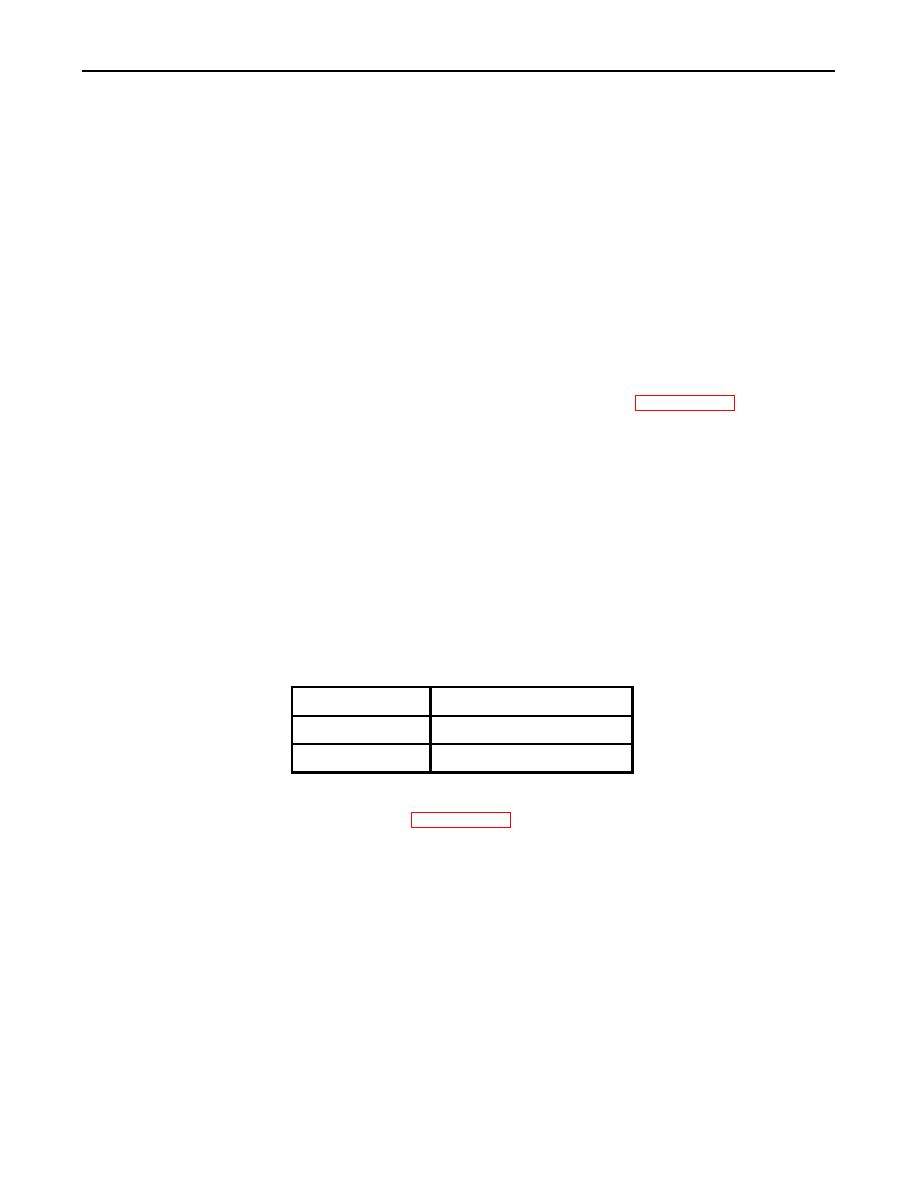

Table 2. Valve Clearance Setting.

VALVE

CLEARANCE

Intake

0.015 in. (0.38 mm)

Exhaust

0.025 in. (0.64 mm)

4.

Tighten jamnut (6) 13-23 lb-ft (18-31 Nm).

5.

Perform fuel injector timing adjustment (WP 0322 00).

0311 00-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |