|

|||

|

|

|||

|

Page Title:

Table 1. Unit Preventive Maintenance Checks and Services - continued |

|

||

| ||||||||||

|

|

TM 9-2320-386-24-1-1

0025 00

Table 1. Unit Preventive Maintenance Checks and Services (Contd).

ITEM TO

EQUIPMENT NOT

ITEM

INTERVAL

CHECK/

READY/AVAILABLE

PROCEDURE

NO.

SERVICE

IF:

31

Semiannually

Front

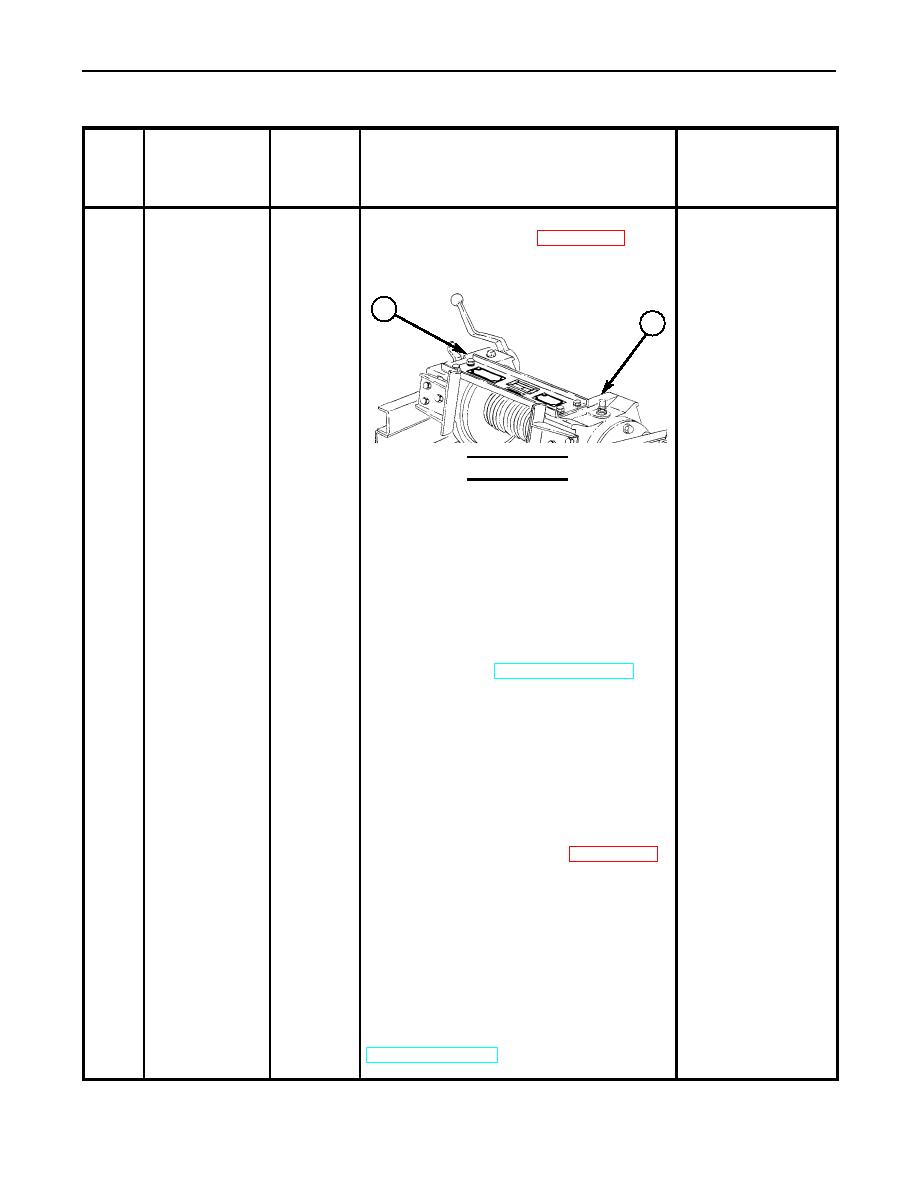

d. Check front winch gearcase (2) and end

(Contd)

winch

frame housing (1) oil level (WP 0023 00).

[RPL]

e. Change front winch filter oil only

when required.

1

2

.WARNING.

Wire rope can become frayed or contain

broken wires. Wear heavy, leather-

palmed work gloves when handling wire

rope. Frayed or broken wires can injure

hands.

Never let moving wire rope slide

through hands, even when wearing

gloves. A broken wire could cut

through glove and cut hand.

f. Unwind entire cable, soak and clean

with new oil, and inspect for kinks, frays,

and wear. Refer to TM 9-2320-386-10 for

operation.

32

Semiannually

Frame and

a. Using a .001-in. (0.025-mm) thick feeler

cross-

gauge, check for space between rivet head and

members

riveted frame member. Penetration of the

feeler gauge between the rivet and the riveted

member is reason to suspect that the riveted

connection and/or rivet should be replaced.

b. Thoroughly clean rivet and riveted

b. Any loose or

connection of all dirt, grease, and oil. Using

missing rivets.

an oil can, apply lubricating oil (WP 0023 00)

around the suspect rivet and riveted

connection. Allow approximately 10-20 seconds

for the oil to penetrate. Wipe rivet and riveted

connection free of oil. Tap rivet with an

8-pound hammer. Any indication of oil

around the rivet indicates a loose rivet. Replace

all loose rivets. Check all riveted connections

for signs of movement, such as bare or shiny

spots, or other indications of movement

between rivet and framing member. If

movement is indicated, rivet and connection

are loose. Repair all loose connections

(TM 9-2320-361-34).

0025 00-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |