|

|||

|

|

|||

|

Page Title:

WHEEL, TIRE, AND TUBE MAINTENANCE - continued |

|

||

| ||||||||||

|

|

TM 9-2320-361-24-1

0186 00

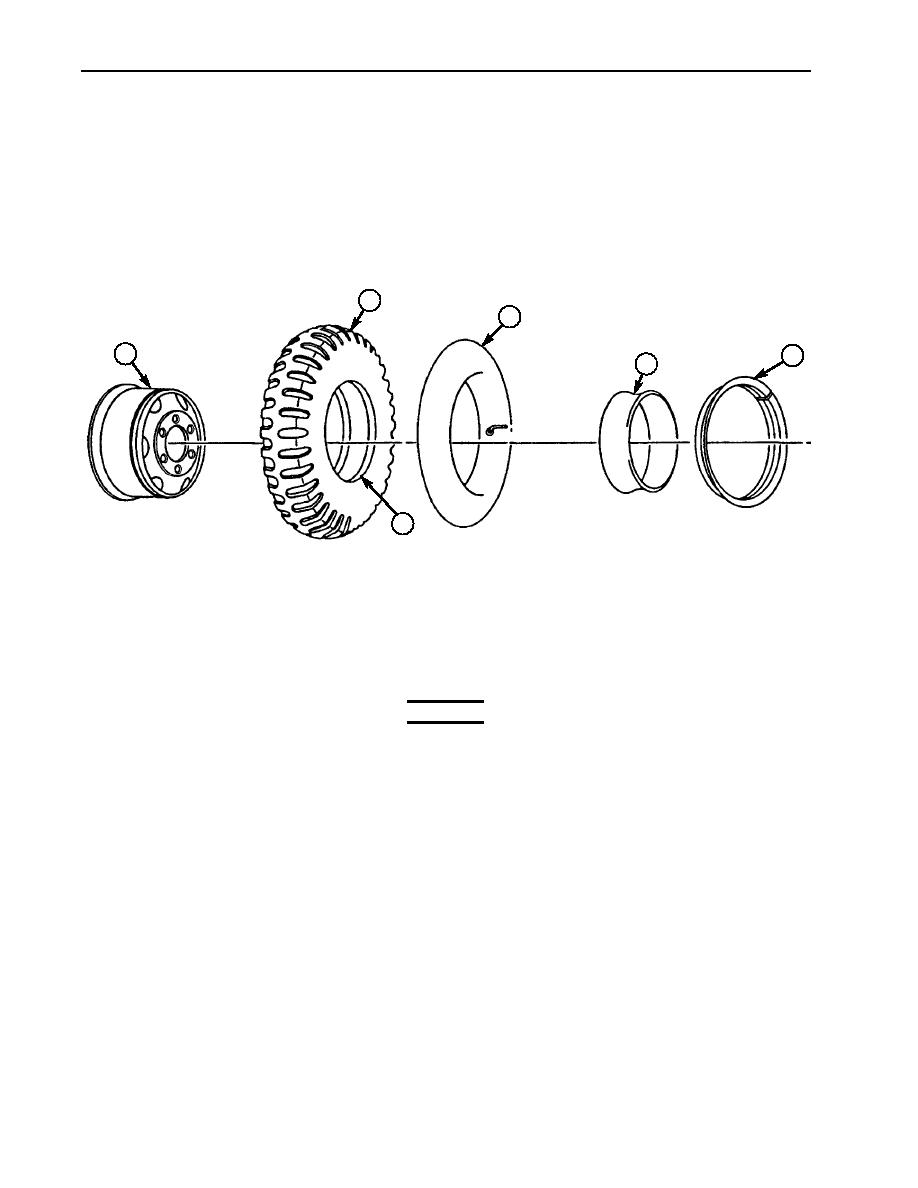

WHEEL, TIRE, AND TUBE MAINTENANCE (Contd)

INSPECTION

1.

Inspect rim (1) and lock ring (5) for bends, cracks, breaks, distortion, or pitting from corrosion.

Replace if bent, cracked, broken, distorted, or pitted from corrosion.

2.

Inspect tire (2), tube (3), and tire liner (4) for cracks, stud hole damage, and bends. Replace if

cracked, stud holes are damaged, or bent.

2

3

1

5

4

6

TIRE AND TUBE INSTALLATION

1.

Use valve cap (8) to screw valve core (9) into valve stem (7), and place tube (3) in tire (2).

2.

Inflate tube (3) enough to hold shape (do not exceed 3 psi (21 kPa)), and install tire liner (4) over

valve stem (7). Ensure tube (3) and tire liner (4) are straight and not pinched.

3.

Install tire (2) and tube (3) on rim (1) and guide valve stem (7) through hole in rim (1), and seat

tire (2) firmly.

WARNING

Lock ring must be properly seated around wheel when

installed. If lock ring is not correctly installed, it may explode

off when tire is inflated, causing injury or death to personnel.

Never attempt to correct seating of lock ring by hammering,

striking, or forcing while tire is inflated. Lock ring may

explode off, causing injury or death to personnel.

4.

Install lock ring (5) into groove of rim (1).

0186 00-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |