|

|||

|

|

|||

|

Page Title:

CYLINDER HEAD MAINTENANCE - continued |

|

||

| ||||||||||

|

|

TM 9-2320-361-24-1

0027 00

CYLINDER HEAD MAINTENANCE (Contd)

INSTALLATION

CAUTION

Do not allow lubricating oil to contact the surface on engine

block where cylinder head gasket bonds. Cylinder head gasket

may become contaminated with oil and fail to seal on engine

block and cylinder head. Failure to comply may cause damage to

equipment.

1.

Apply thin coat of clean lubricating oil on threads of fourteen studs (5) and nut (1) facings.

CAUTION

Ensure cylinder head does not bind on studs during installation.

Bending of studs may cause cylinder head to guide pin

misalignment. Cylinder head cannot be installed on engine

block if misaligned. Failure to comply may cause damage to

equipment.

2.

Install new gasket (3) and cylinder head (2) on fourteen studs (5) and engine block (4) with

fourteen washers (10) and nuts (1).

NOTE

If studs rotate when torquing nuts, remove cylinder head and

repair or replace studs.

3.

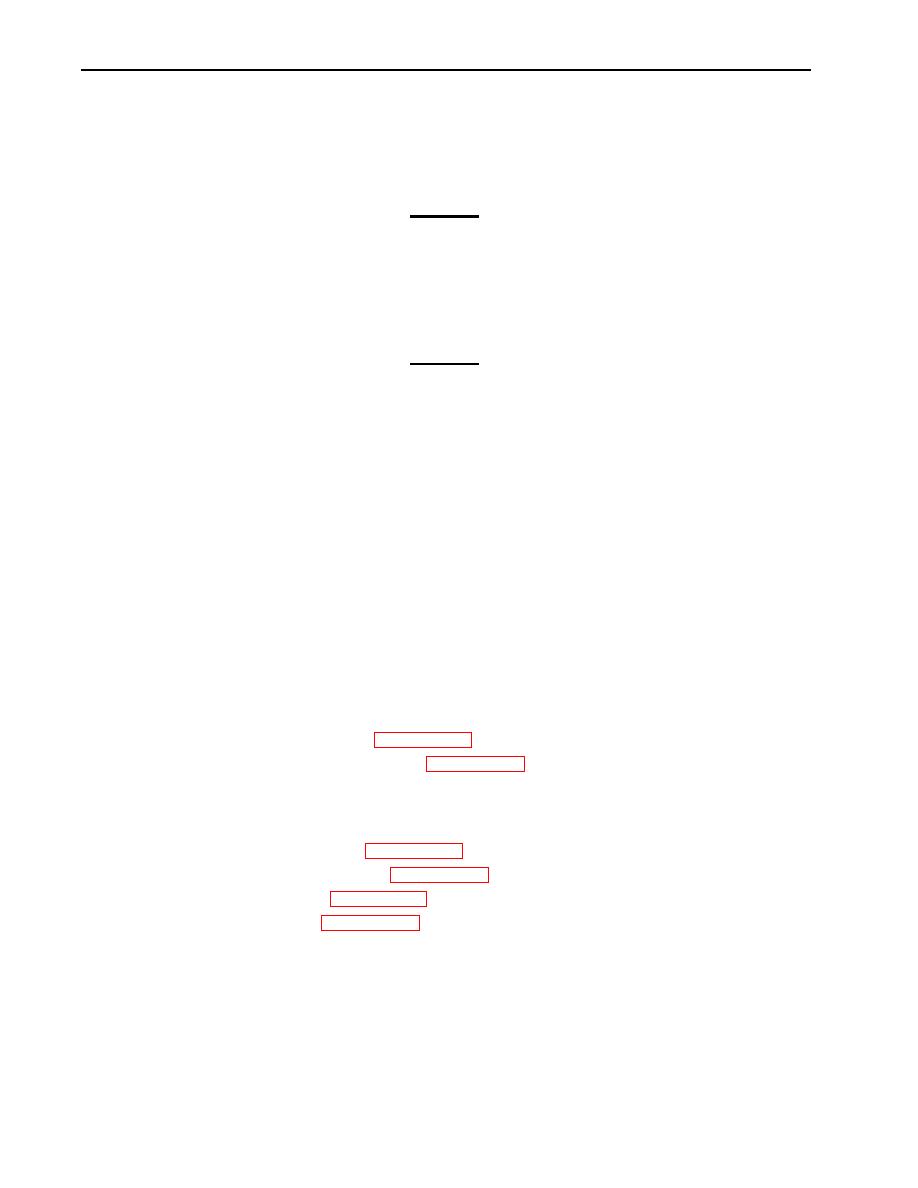

Tighten fourteen nuts (1) to 40 lb-ft (54 Nm) in torque sequence shown.

a. Using torque sequence, tighten nuts (1) to 110 lb-ft (149 Nm).

b. Using torque sequence, tighten nuts (1) to 130 lb-ft (176 Nm).

c. Using torque sequence, tighten nuts (1) to 157 lb-ft (204 Nm).

d. Using torque sequence, tighten nuts (1) to 157 lb-ft (204 Nm).

4.

Install lifting bracket (9) and bracket (6) on cylinder head (2) with two new lockwashers (7) and

screws (8).

5.

Install intake and exhaust manifolds (WP 0041 00).

6.

Install and adjust rocker arms and pushrods (WP 0031 00).

NOTE

Do not apply sealing compound on rocker arm cover gasket at

this time.

7.

Install rocker arm cover and gasket (WP 0030 00).

8.

Install fuel injector nozzles and holders (WP 0067 00).

9.

Install air intake tube and cap (WP 0051 00).

10.

Connect battery ground cable (WP 0126 00).

0027 00-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |