|

|||

|

|

|||

|

Page Title:

Table 1. Engine Troubleshooting Procedures |

|

||

| ||||||||||

|

|

TM 9-2320-361-24-1

0008 00

MECHANICAL SYSTEMS TROUBLESHOOTING - DIRECT SUPPORT (Contd)

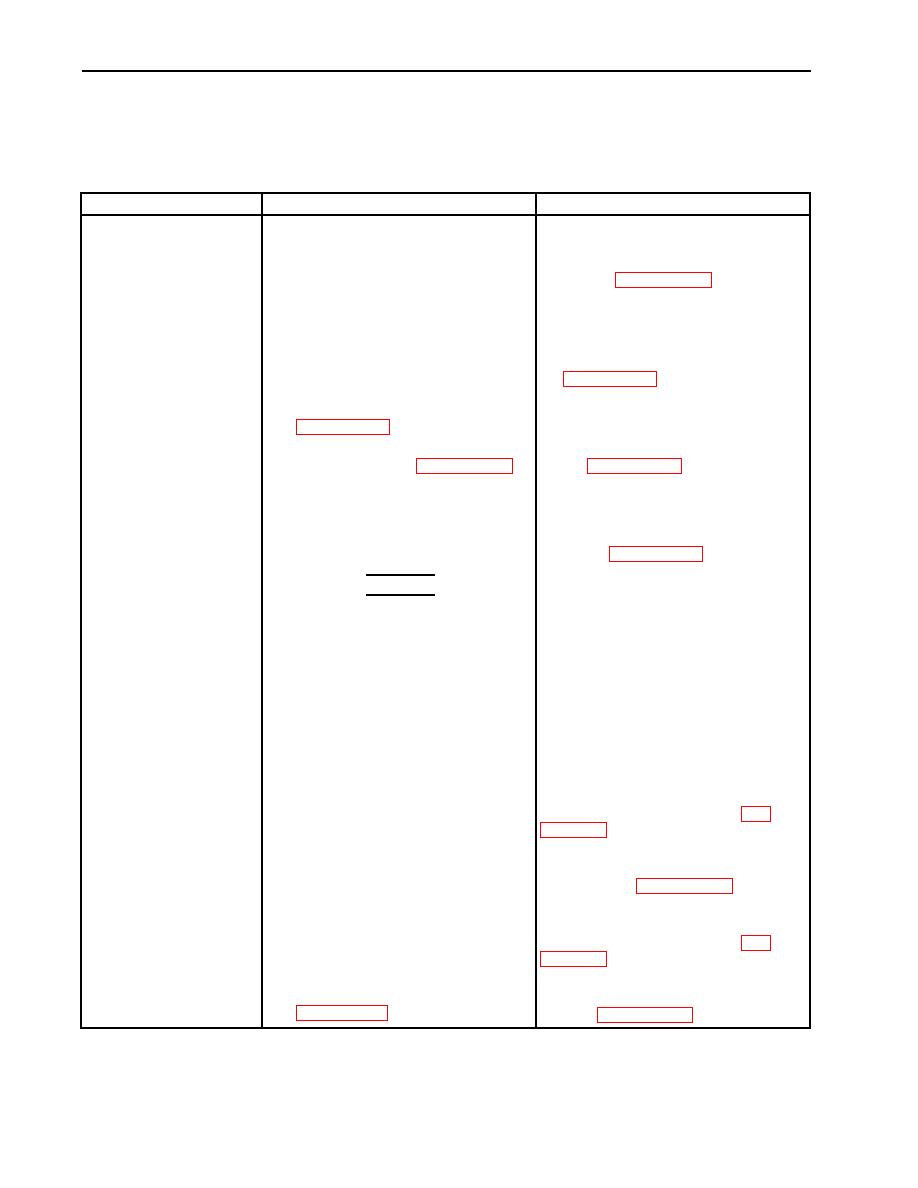

Table 1. Engine Troubleshooting Procedures (Contd).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3. If engine crankshaft will not turn

1. ENGINE WILL NOT

or turns hard, check internal

CRANK (Contd)

components for seizure. Remove

oil pan (WP 0035 00) and inspect

crankshaft for nicks, burns,

grooves, scuffs, or discoloration

due to overheating. If nicked,

burned, grooved, scuffed, or

discolored replace engine

5. Install fuel injector nozzle

6. Check oil pump for seizure.

If drive gear will not turn, replace oil

Remove oil pump (WP 0036 00)

pump (WP 0036 00).

and manually turn oil pump

drive gear.

7. Check air intake manifold for

If water is present within air cleaner,

presence of water.

disassemble and drain air intake

manifold (WP 0041 00).

CAUTION

Starting engine after correcting

piston fluid-locked condition must be

done with care. When pistons have

been fluid-locked within cylinders,

connecting rods may have been

damaged and can be identified

during test run by abnormal

vibration or noise. Do not operate

engine when these conditions exist.

Permanent engine damage may

result.

If engine operates with unusual

8. Remove water from air induction

sounds or vibration, refer to WP

system, if present and perform

an engine test run.

or 17.

9. Check turbocharger housing for

If water is present, replace

presence of water, identified by

turbocharger (WP 0057 00).

water on turbocharger fins or

hubs.

10. Test run engine.

If engine operates with unusual

sounds or vibration, refer to WP

or 17.

11. Remove intake manifold and

gasket. Inspect for defects

If intake manifold is defective,

replace (WP 0041 00).

0008 00-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |