|

|||

|

|

|||

|

Page Title:

Inspection and Repair - continued |

|

||

| ||||||||||

|

|

TM 9-2320-209-34-2-3

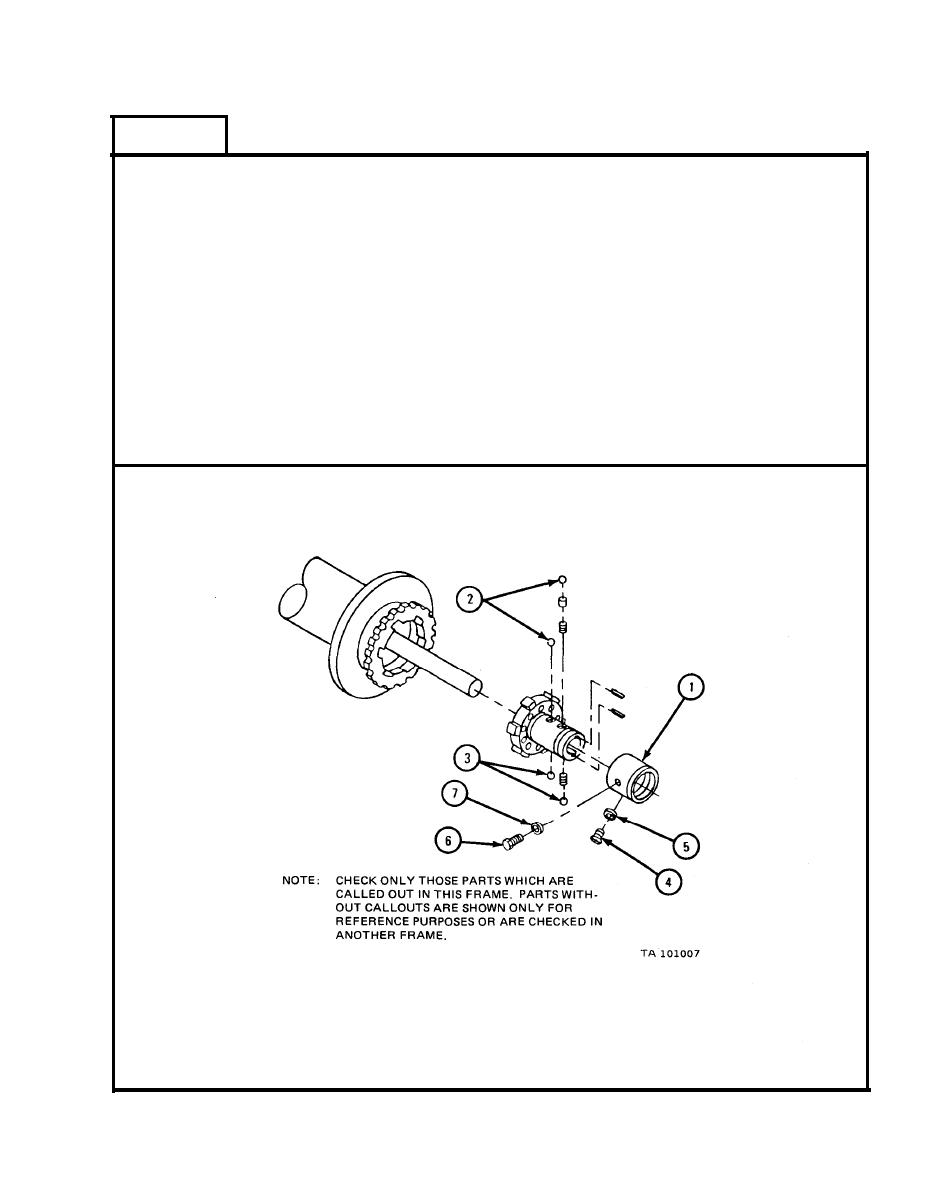

FRAME 8

1.

Check that clutch detent sleeve (1) is not cracked. If clutch detent sleeve is

cracked, get a new one.

2.

Check that clutch detent sleeve (1) has no outer damage. If clutch detent

sleeve has outer damage, get a new one.

Check inner diameter of clutch detent sleeve for deep lengthwise grooving

3.

caused by the action of balls (2 and 3).

If two sets of wear grooves are present, take out capscrew (4) and washer (5)

4.

in their present location and install in hole formerly occupied by screw (6)

and washer (7).

If four sets of wear grooves are present, then capscrew (4) and washer (5)

5.

have previously been moved. Put in new clutch detent sleeve (1). Put

capscrew (4) and washer (5) back into their original position on new sleeve.

GO TO FRAME 9

18-107

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |