|

|||

|

|

|||

|

Page Title:

Inspection and Repair - continued |

|

||

| ||||||||||

|

|

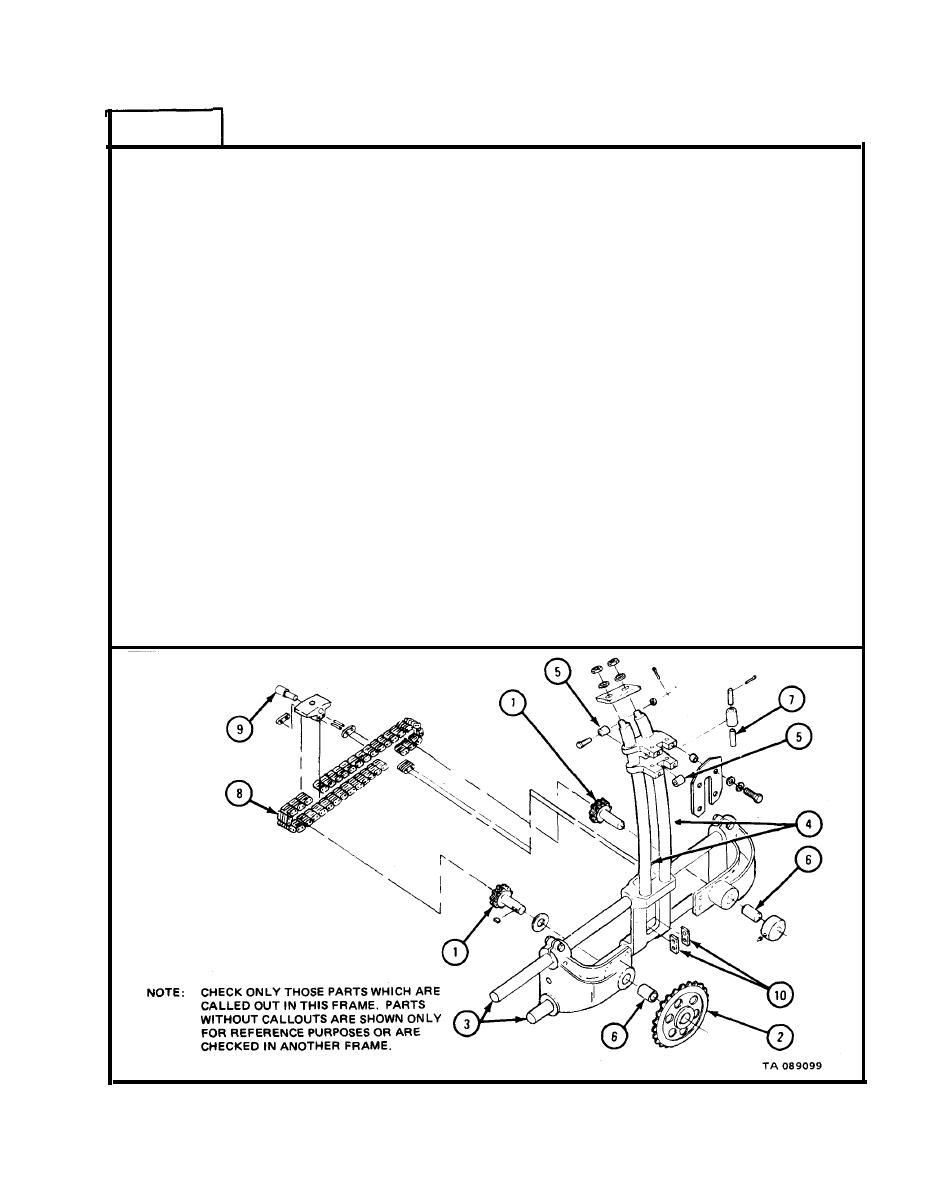

TM 9-2320-209-34-2-3

FRAME

5

Check that two sprockets (1) and sprocket (2) are not chipped or have

1.

broken teeth. If sprockets are damaged, get new ones.

2.

Check that shaft portions of sprockets (1 and 2) are not distorted, burred,

nicked or scratched. Smooth out raised metal, nicks, or scratches with

a honing stone and polish with a crocus cloth.

Check that tie rods (3) and horns (4) are not cracked. If shafts are damaged,

3.

get new ones.

Check that tie rods (3) and horns (4) are not bent, burred, nicked, or

4.

scratched. If shafts are damaged, get new ones. Smooth out raised metal,

nicks, or scratches with a honing stone and polish with a crocus cloth.

Check that bearings (5, 6, and 7) are not pitted, burred) grooved, or

5.

rough. Polish small damage with a crocus cloth.

Check that bearings (5, 6, and 7) are not cracked. If bearings are cracked,

6.

get new ones.

Check that cross chain (8) is not damaged or has broken links. If cross

7.

chain is damaged or has broken links, get new links or chain assembly.

Check that guide pin (9) has no flat areas on wear plate portion of pin.

8.

Turn guide pin in chain guide if damage is small. If guide pin is damaged in

any other way, get new one.

Check that wear plates (10) do not have uneven wear spots. If wear plates

9.

are damaged, get new ones.

GO TO FRAME 6

18-103

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |