|

|||

|

|

|||

|

Page Title:

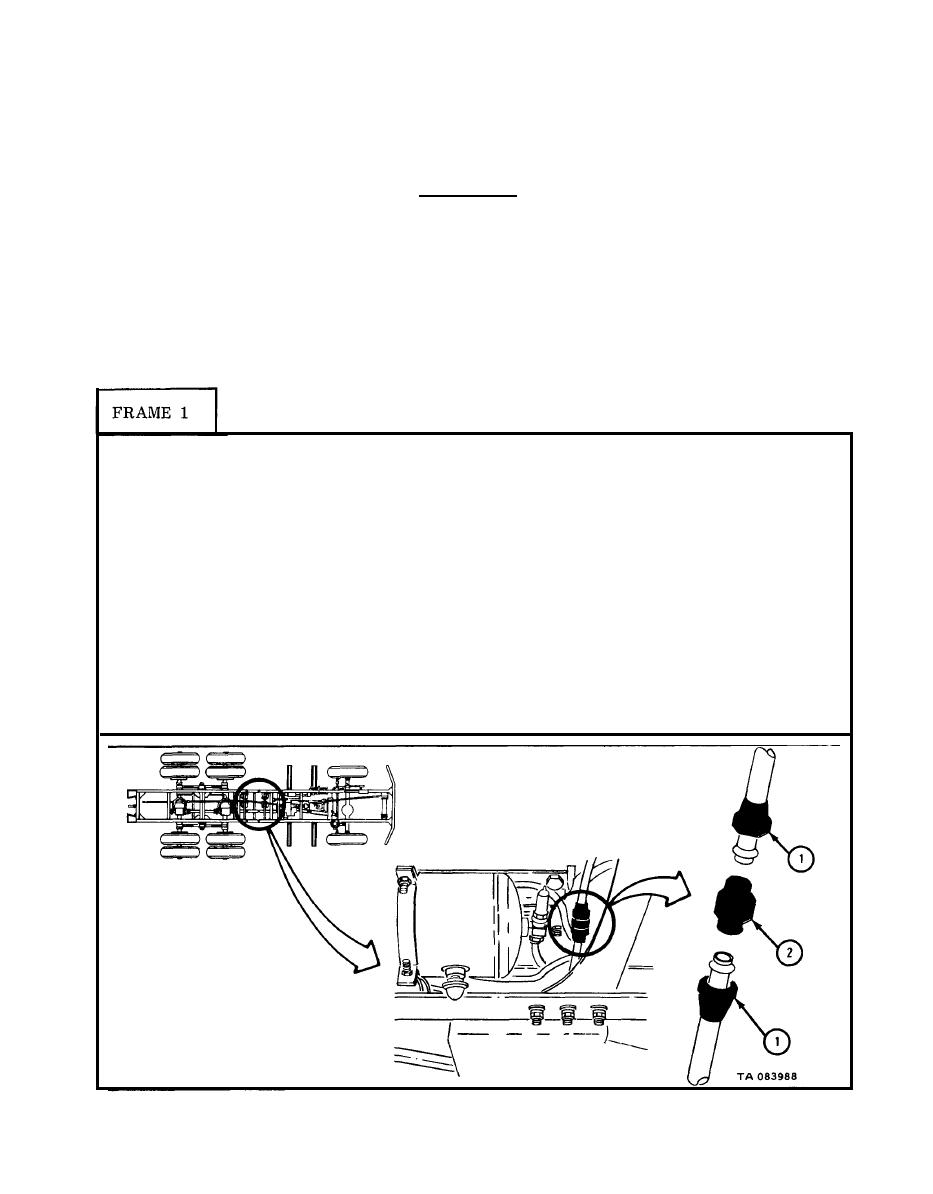

AIR SYSTEM LINES AND FITTINGS REMOVAL AND REPLACEMENT - continued |

|

||

| ||||||||||

|

|

TM

9-2320-209-20-3-2

(2)

Air

tube

fittings.

(a)

Air

tube

connecting

nipple

CAUTION

Fittings

are

made

of

soft

brass.

They

can

be

stripped

if

tightened

too

much.

Tighten

fittings

just

enough

to

stop

air

from

leaking.

NOTE

The

air

tube

connecting

nipple

on

the

left

side

of

chassis

of

truck

M764

is

used

for

this

typical

procedure.

Screw

two

tube

nuts

(1)

onto

adapter

fitting

(2).

1.

Using

11/16-inch

combination

box

and

open

end

box

wrench,

hold

adapter

2.

fitting

(2).

Using

13/16-inch

combination

box

and

open

end

box

wrench,

tighten

two

tube

3.

nuts

(1).

NOTE

Follow-on

Maintenance

Action

Required:

Start

engine

and

let

it

run

until

air

pressure

gage

1.

reads

between

65

and

125

psi.

Refer

to

TM 9-2320-209-10.

Refer to TM 9-2320-209-10.

2.

Stop engine.

Do air system leak test.

Refer to Part 1,

para

1-5.

3.

END

OF

TASK

13-158

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |