|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-386-24-1-2

0298 00

STARTING REPAIRED OR REPLACED ENGINE (Contd)

3.

Start and idle engine (TM 9-2320-386-10) at 800-1000 RPM for five to ten minutes, observing oil

pressure. If oil pressure drops below 10 psi (69 kPa) or rises sharply above 30 psi (207 kPa), stop

engine (TM 9-2320-386-10) and correct as necessary. Refer to mechanical troubleshooting

(WP 0010 00).

4.

Stop engine and check oil and coolant levels (TM 9-2320-386-10).

NOTE

It may be necessary to block air flow to radiator.

5.

Inspect for leaks. If leaks exist, correct as necessary.

NOTE

Engine idle speed check and adjustment cannot be made on a cold

engine.

Check that engine idle speed is 750-850 RPM. If it is not, perform

step 7.

6.

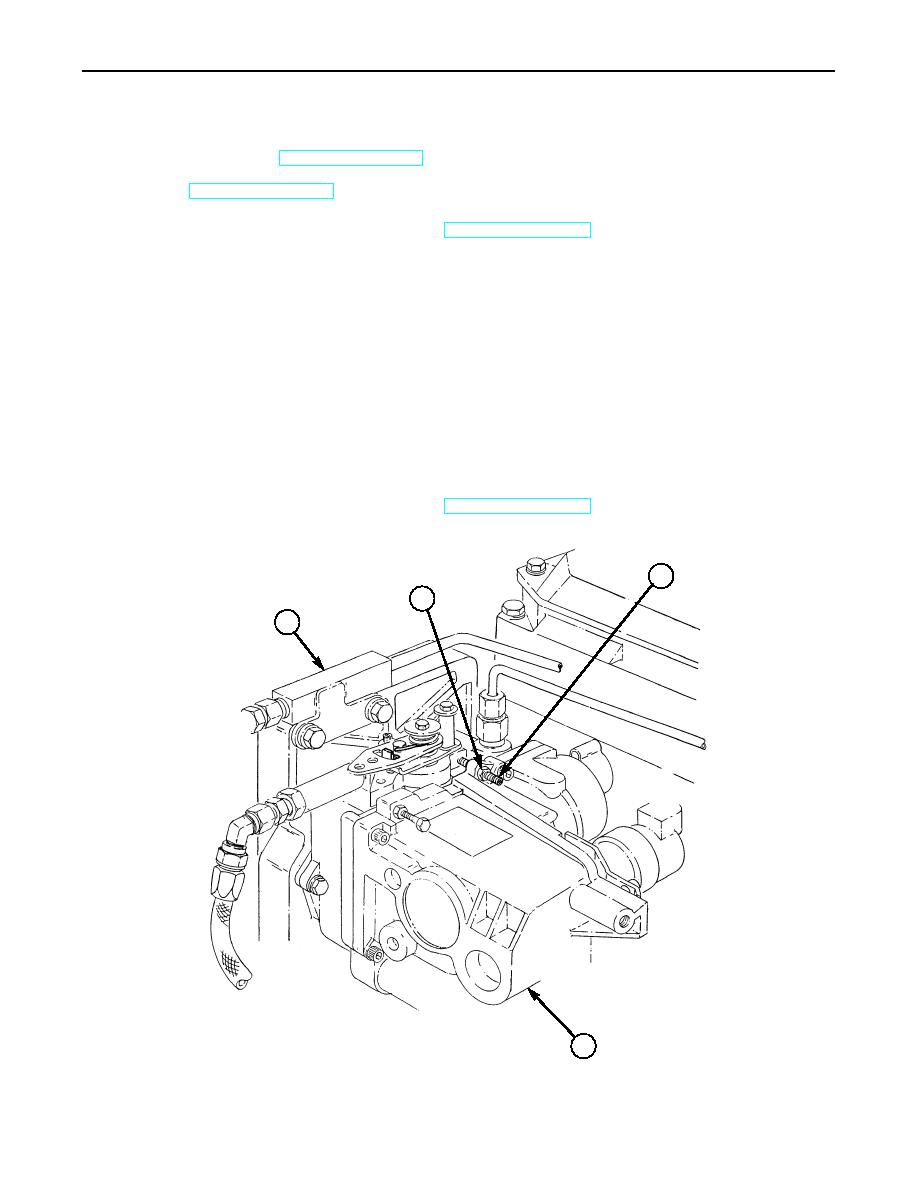

Operate engine (1) for fifteen minutes at 2100 RPM and observe oil pressure until coolant

temperature reaches 165-195F (74-91C).

7.

Loosen jamnut (2) and turn adjusting screw (3) on fuel pump (4) clockwise to increase idle speed, or

counterclockwise to decrease idle speed. Correct idle speed to 750-850 RPM and tighten jamnut (2).

8.

Stop engine and check oil and coolant levels (TM 9-2320-386-10).

3

2

1

4

END OF WORK PACKAGE

0298 00-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |