|

|||

|

|

|||

|

Page Title:

TUBING APPLICATION TIGHTENING ASSEMBLY INSTRUCTIONS |

|

||

| ||||||||||

|

|

TM 9-2320-361-24-2

0472 00

TORQUE LIMITS (Contd)

TUBING APPLICATION TIGHTENING ASSEMBLY INSTRUCTIONS

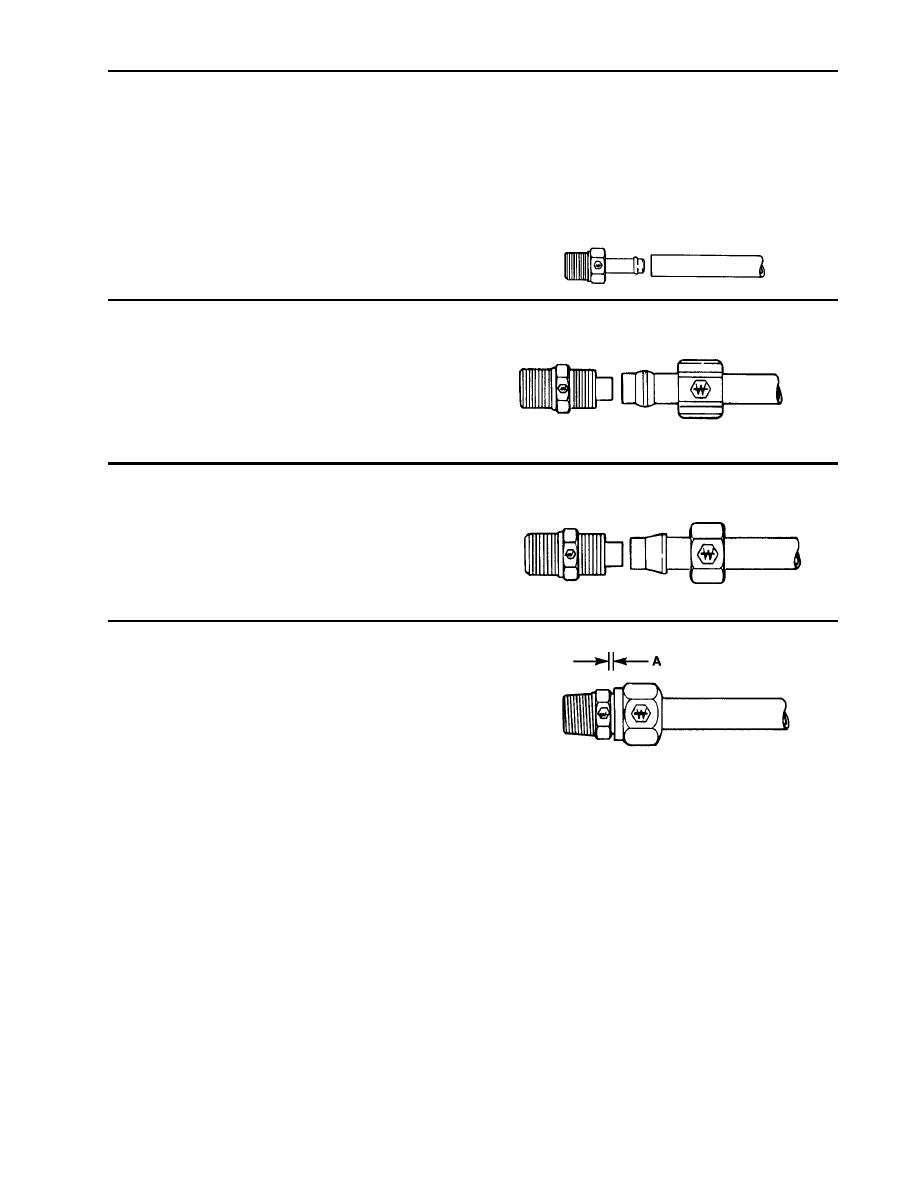

MINI BARB

Slide tubing over barbed insert until it bottoms

on fitting.

KNURL-ON

1.

Slide nut and then sleeve on tubing.

2.

Slide Inner Diameter (I.D.) of tubing onto

fitting insert until it bottoms.

3.

Assemble nut to fitting body.

4.

Tighten assembly finger tight to cover body

threads.

SELF-ALIGN-PTF

1.

Slide nut and then sleeve on tubing.

2.

Slide I.D. of tubing onto fitting insert until

it bottoms.

3.

Assemble nut to fitting body.

4.

Finger tighten nut. From that point,

tighten with a wrench two complete turns.

NYLON TUBING FOR AIR BRAKE

1.

Cut tubing to desired length. Ensure ends

are currently reasonably square.

2.

Slide tubing into preassembled fitting and

push until tube bottoms.

3.

Tighten nut as indicated in chart. Another

check on proper assembly is dimension A ,

when nut is fully tightened.

DISASSEMBLY--Remove nut and pull tubing out

TUBE

TIGHTEN NUT TO

A

of fitting body. Insert will remain on tubing.

O.D.

ASSEMBLY--Push tubing and insert into fitting

85115 lb-in.(9.613.0 Nm) .085.105

1/4

body until it bottoms. Thread nut onto fitting

3/8

1217 lb-ft (16.323.0 Nm)

.125.145

body and tighten as in step 3.

1/2

2533 lb-ft (33.944.7 Nm)

.100.120

5/8

2635 lb-ft (35.347.5 Nm)

.115.135

3/4

3850 lb-ft (51.567.8 Nm)

.180.200

0472 00-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |