|

|||

|

|

|||

|

Page Title:

DIFFERENTIAL CARRIER REPAIR - continued |

|

||

| ||||||||||

|

|

TM 9-2320-361-24-2

0455 00

DIFFERENTIAL CARRIER REPAIR (Contd)

CLEANING AND INSPECTION (Contd)

24.

Inspect carrier housing (12), two bearing caps (6), and adjusting nuts (10). Replace carrier

housing (12) if bearing caps (6) are cracked or distorted. Replace carrier housing (12) or adjusting

nuts (10) if cracked, cross-threaded, or stripped.

25.

Inspect two bearings (1) and bearing seats (11) and (13) for chips or distortion. Replace

bearings (1) or bearing seats (11) and (13) if chipped or distorted.

26.

Measure inside diameter of inner race on two bearings (1). Refer to table 3, Wear Limits, for

measurements. Replace bearings (1) if not within wear limits.

27.

Inspect two case halves (2) for chips, cracks, or distortion. Replace differential assembly (14) if case

halves are chipped, cracked, or distorted.

28.

Measure outside diameter of case halves (2) at point where bearing (1) inner race fits. Refer to

table 3, Wear Limits, for measurements. Replace differential assembly (14) if case halves (2) are

not within wear limits.

29.

Inspect helical drive gear (5) teeth for chips, breaks, cracks, burrs, or uneven wear. Replace helical

drive gear (5) if teeth are chipped, broken, cracked, burred, or worn unevenly.

30.

spider (7) for chips, breaks, cracks, burrs, or uneven wear. Replace two thrust washers (3), side

cracked, burred, or worn unevenly.

31.

Measure inside diameter of four pinion gears (8). Refer to table 3, Wear Limits, for measurements.

spider (7) if any pinion gear (8) is not within wear limits.

32.

Measure outside diameter of each arm of spider (7). Refer to table 3, Wear Limits, for

measurements. Replace two thrust washers (3), side gears (4), four thrust washers (9), pinion

gears (8), and spider (7) if any arm of spider (7) is not within wear limits.

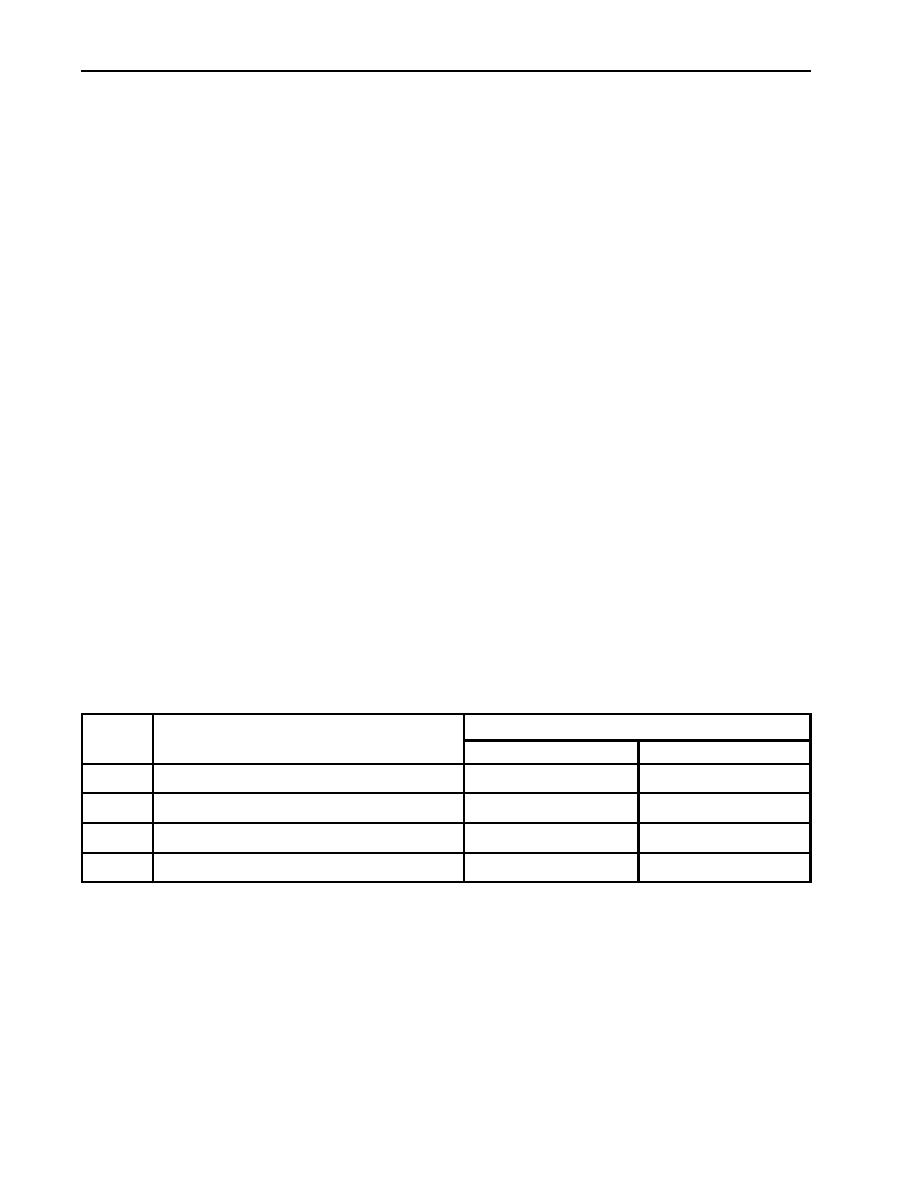

Table 3. Wear Limits.

WEAR LIMITS/TOLERANCE

ITEM NO.

ITEM/POINT OF MEASUREMENT

INCHES

MILLIMETERS

1

Bearing (inside diameter of inner race)

2.500--2.501

63.500--63.525

2

Case half (outside diameter)

2.504--2.505

63.602--63.627

7

Spider (outside diameter of arms)

0.870--0.880

22.098--22.352

8

Pinion gear (inside diameter)

0.877--0.879

22.276--22.327

0455 00-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |