|

|||

|

|

|||

|

Page Title:

DISCHARGE VALVE REPAIR - continued |

|

||

| ||||||||||

|

|

TM 9-2320-361-24-2

0265 00

DISCHARGE VALVE REPAIR (Contd)

CLEANING AND INSPECTION

WARNING

Skysol 100 solvent is combustible; DO NOT use or store near

heat, sparks, flame, or other ignition sources. Use mechanical

ventilation whenever product is used in a confined space, heated

above ambient temperatures, or agitated. Keep container sealed

when not in use.

Contact with Skysol 100 may cause skin irritation. Use

chemical-resistant gloves. In case of skin contact, remove any

contaminated clothing and wash skin thoroughly with soap and

water. Wash contaminated clothing before reuse. Eye contact

may cause irritation, tearing, or blurring of vision. Use face

shield or goggles when eye contact may occur. In case of eye

contact, flush eyes with large amounts of water for at least 15

minutes or until irritation subsides. Inhalation may cause

irritation to upper respiratory passages. DO NOT have food or

drink in the vicinity. Failure to comply may result in injury to

personnel.

NOTE

Perform step 1 for cleaning M49A2C fuel tank discharge

valves.

Perform step 2 for cleaning M50A3 water tank discharge

valves.

1.

Wash all parts with Skysol 100 solvent and allow to air dry.

2.

Wash all parts with soap and hot water. Rinse all parts with hot water and dry using a clean,

soft rag.

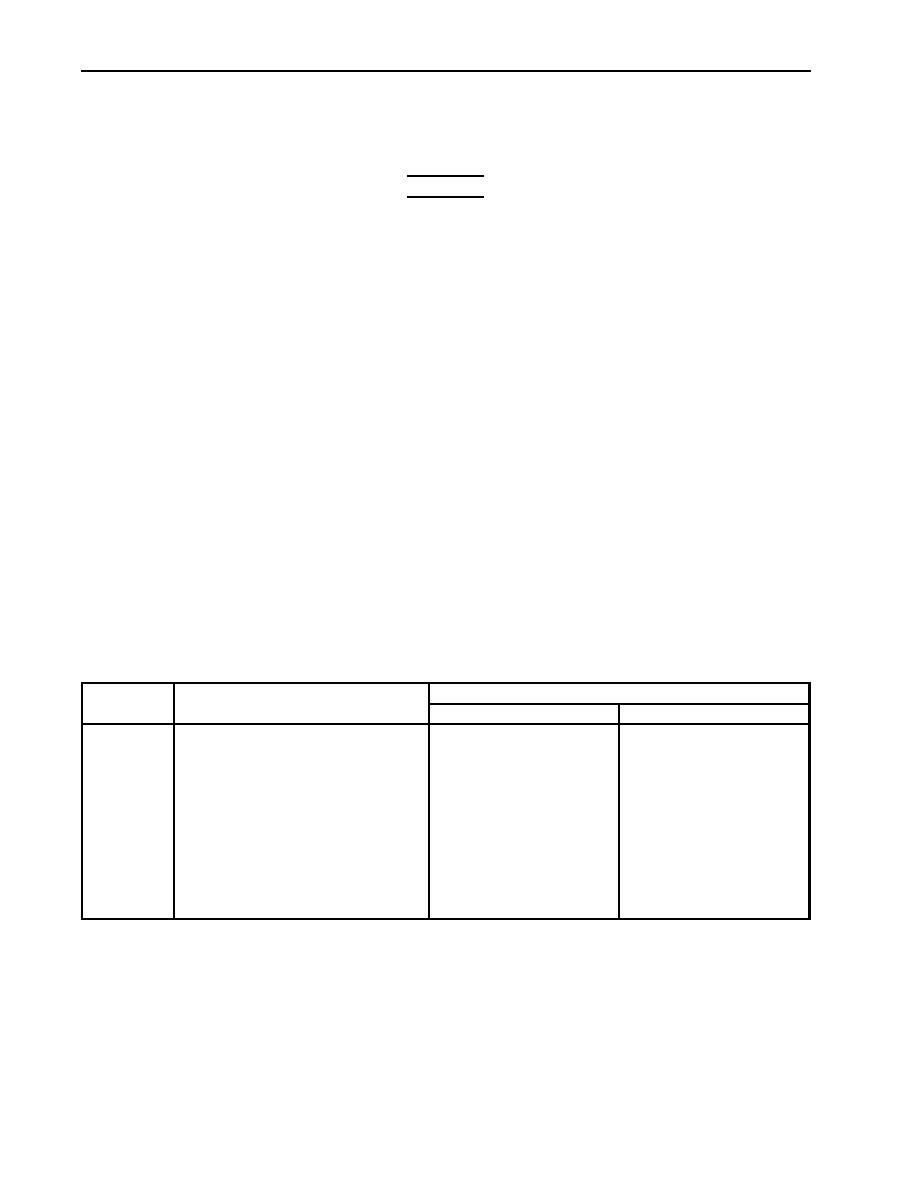

Table 1. Discharge Valve Wear Limits.

WEAR LIMITS/TOLERANCE

ITEM NO.

ITEM/POINT OF MEASUREMENT

INCHES

MILLIMETERS

4

Spring (free length)

5.0

127.0

Cam stem:

7

Inside stem bore end diameter

0.4220.437

10.7211.10

Plug end diameter

0.6440.648

16.3616.46

Machined with square

0.4970.500

11.0012.70

Discharge valve housing:

9

Inside stem bore/inner diameter

0.4330.443

10.9911.25

Outer stem bore/inner diameter

0.6510.661

16.5316.79

3.

Inspect cam stem (7) for scoring or cracks and wear. Refer to table 1, Discharge Valve Wear Limits,

for measurements. Replace if damaged or worn past limits.

4.

Inspect strainer (2) for tears. Replace if damaged.

5.

Inspect valve housing (9) for cracks, stripped threads, scoring, or worn bores. Refer to table 1,

Discharge Valve Wear Limits, for measurements. Replace if damaged or worn past limits.

6.

Inspect cap (3) for wear or cracks at stem hole. Replace if damaged.

7.

Inspect holder (1) for wear or cracks at tapered stem hole. Replace if damaged.

8.

Inspect retainer (10) for cracks or damaged threads. Replace if damaged.

0265 00-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |