|

|||

|

|

|||

|

Page Title:

DISCHARGE VALVE CONTROL LEVERS MAINTENANCE (M49A2C) - continued |

|

||

| ||||||||||

|

|

TM 9-2320-361-24-2

0264 00

DISCHARGE VALVE CONTROL LEVERS MAINTENANCE (M49A2C) (Contd)

DISASSEMBLY

CAUTION

Do not strike levers or brackets during lever shaft removal.

Striking levers or brackets may result in damage to

components.

NOTE

Prior to removal, tag all components for assembly.

1.

Remove springs (31) and (22) from lever arms (14) and (21) and brackets (30) and (23).

2.

Remove three screws (6) and lockwashers (7) from brackets (5), (30), and (23). Discard

lockwashers (7).

3.

Remove lever shaft (8) and levers (4) and (28) from between brackets (5), (30), and (23).

4.

Remove cotter pins (15) and (16) and fusible link (17) from lever arm (14) and bracket (30).

Discard cotter pins (15) and (16).

5.

Remove setscrews (12) and (20) in cams (13) and (19). Remove shaft (9) from bushing (24), lever

arm (21), cam (20), bushing (29), lever arm (14), cam (13), and bushing (10). Remove cams (13)

and (20).

6.

Remove rollers (18) and (11) from bushings (10) and (29).

7.

Remove lever arms (14) and (21) from bushings (29) and (24).

8.

Remove cotter pin (27) from pin (25) and remove pin (25) and clevis (26) from lever arm (21).

Discard cotter pin (27).

9.

Remove three screws (2), lockwashers (3), and spacer bar (1) from brackets (5), (30), and (23).

Discard lockwashers (3).

CLEANING AND INSPECTION

1.

Refer to WP 0021 00 for general cleaning instructions.

2.

Refer to WP 0020 00 for general inspection instructions.

3.

Inspect clevis (26) and pin (25) for cracks or pin hole damage. Replace clevis (26) and pin (25) if

cracked or pin hole is damaged.

4.

Inspect shaft (9) for twists, cracks, or breakage. Replace shaft, (9) if twisted, cracked, or broken.

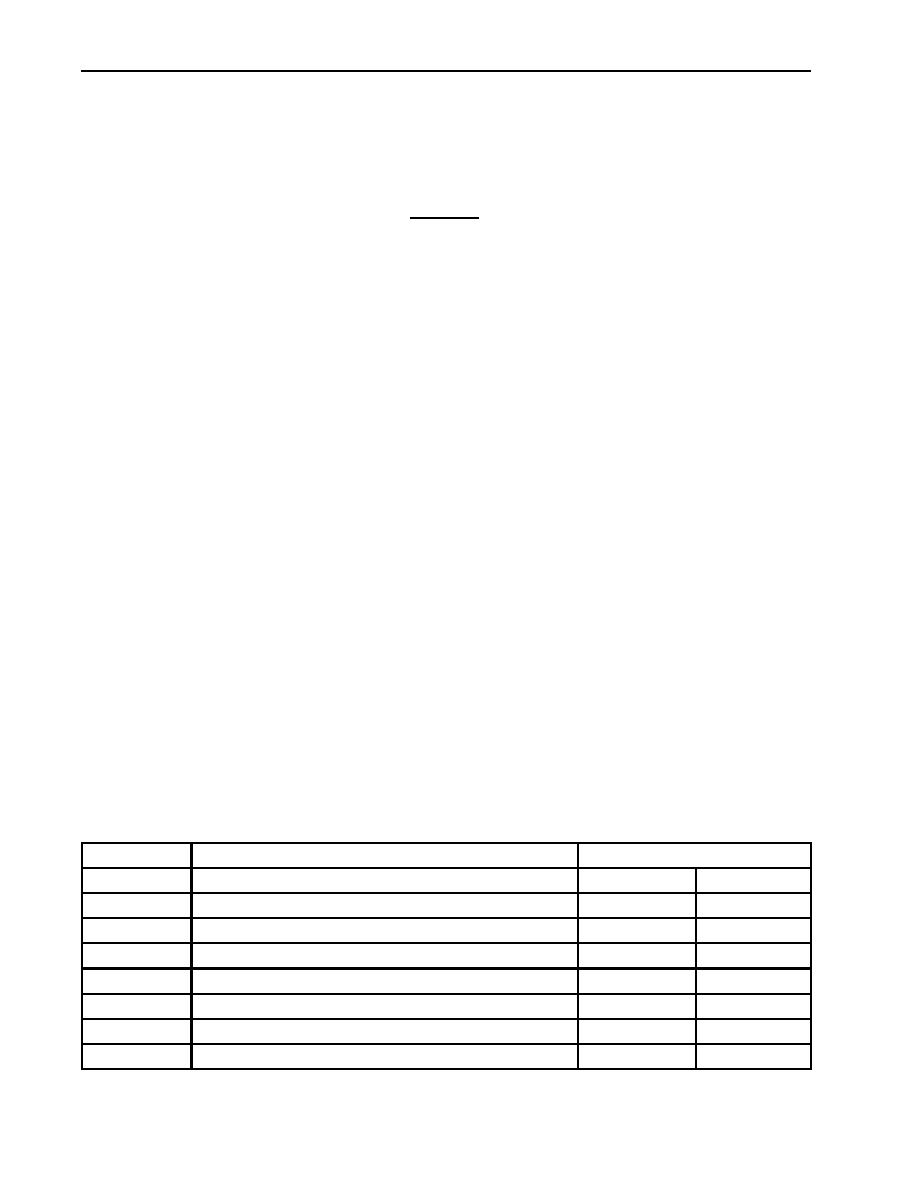

ITEM NO

ITEM/POINT OF MEASUREMENT

WEAR LIMITS/TOLERANCE

INCHES

MILLIMETERS

21

Lever arm (inner diameter at shaft hole)

0.4.330.463

11.2511.76

14

Lever arm (inner diameter at shaft hole)

0.4300.454

10.9211.53

4 and 28

Levers (inner diameter at shaft hole)

0.8680.922

22.0523.42

10, 24, and 29 Bushings end exposed (diameter)

0.4300.438

10.9211.13

8

Lever shaft (diameter)

0.8600.885

21.8422.48

11 and 18

Roller (outer diameter)

0.750

19.05

11 and 18

Roller (inner diameter)

0.4400.444

11.1811.28

0264 00-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |