|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-361-24-1

FIELD MAINTENANCE INSTRUCTIONS

2-1/2 TON, 6X6, M44A2 SERIES TRUCKS (MULTIFUEL)

WHEEL BEARING ADJUSTMENT

INITIAL SETUP:

Applicable Models

Equipment Condition

All

Parking brake set and wheels chocked

(TM 9-2320-361-10).

Materials/Parts

Battery ground cable disconnected

Key washer (item 375, WP 0470 00)

Front axle shaft flange removed (WP 0146 00).

Rear axle shaft removed (WP 0147 00).

References

WHEEL BEARING ADJUSTMENT

NOTE

Wheel must turn freely prior to wheel bearing adjustment.

Adjustment procedures for front and rear wheel bearings are

the same.

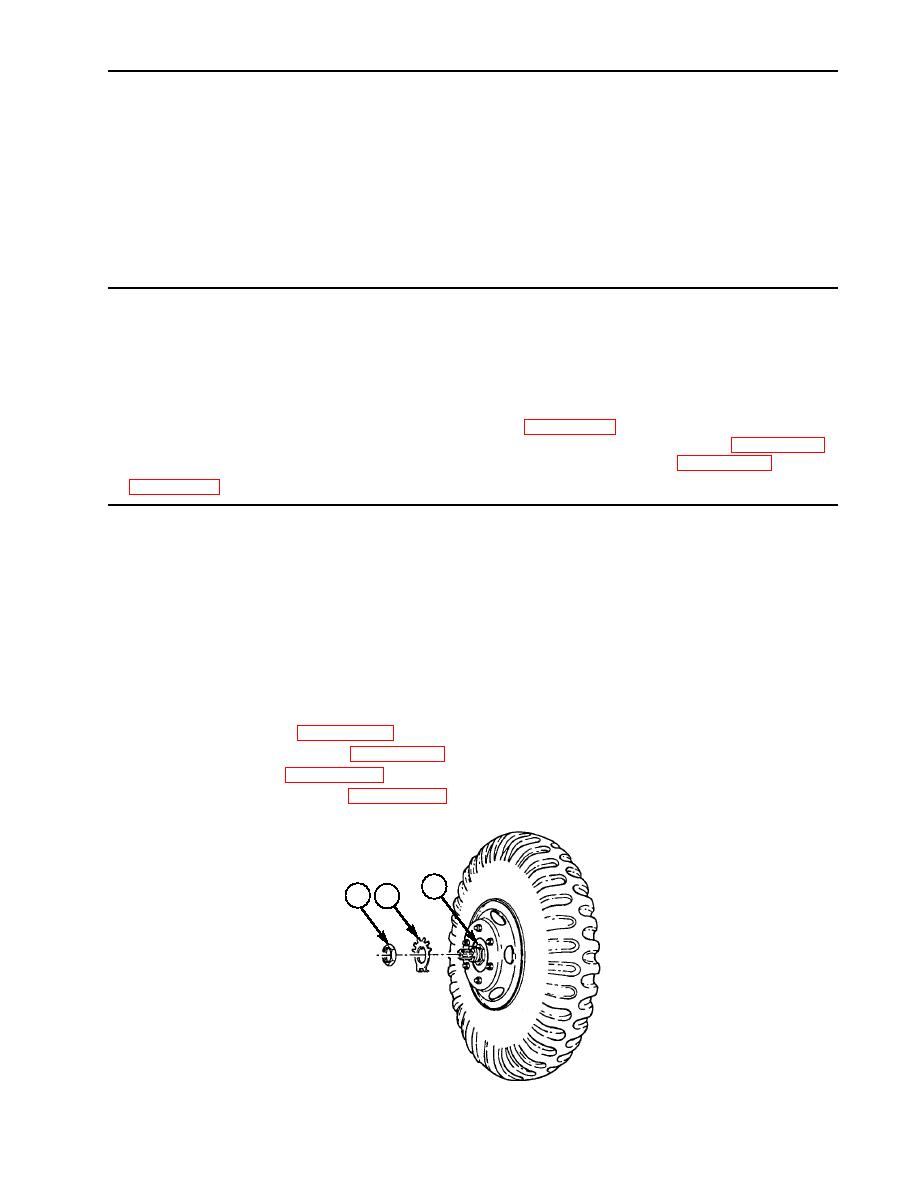

1.

Bend tabs back on key washer (2) and remove outer adjusting nut (1) and key washer (2). Discard

key washer (2).

2.

Turn wheel, tighten inner adjusting nut (3) 50 lb-ft (68 Nm), then back off nut (3) 1/16 to 1/4 turn.

3.

Install new key washer (2) and outer adjusting nut (1). Tighten nut (1) 100200 lb-ft

(136272 Nm).

4.

Bend tabs on key washer (2) down, over inner and outer adjusting nuts (3) and (1).

5.

Install rear axle shaft (WP 0147 00).

6.

Install front axle shaft flange (WP 0146 00).

7.

Adjust service brake (WP 0168 00).

8.

Connect battery ground cable (WP 0126 00).

9.

Release parking brake and remove wheel chocks (TM 9-2320-361-10).

3

1

2

END OF WORK PACKAGE

0189 00-1/2 blank

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |