|

|||

|

|

|||

|

Page Title:

FRONT HUB AND DRUM MAINTENANCE - continued |

|

||

| ||||||||||

|

|

TM 9-2320-361-24-1

0187 00

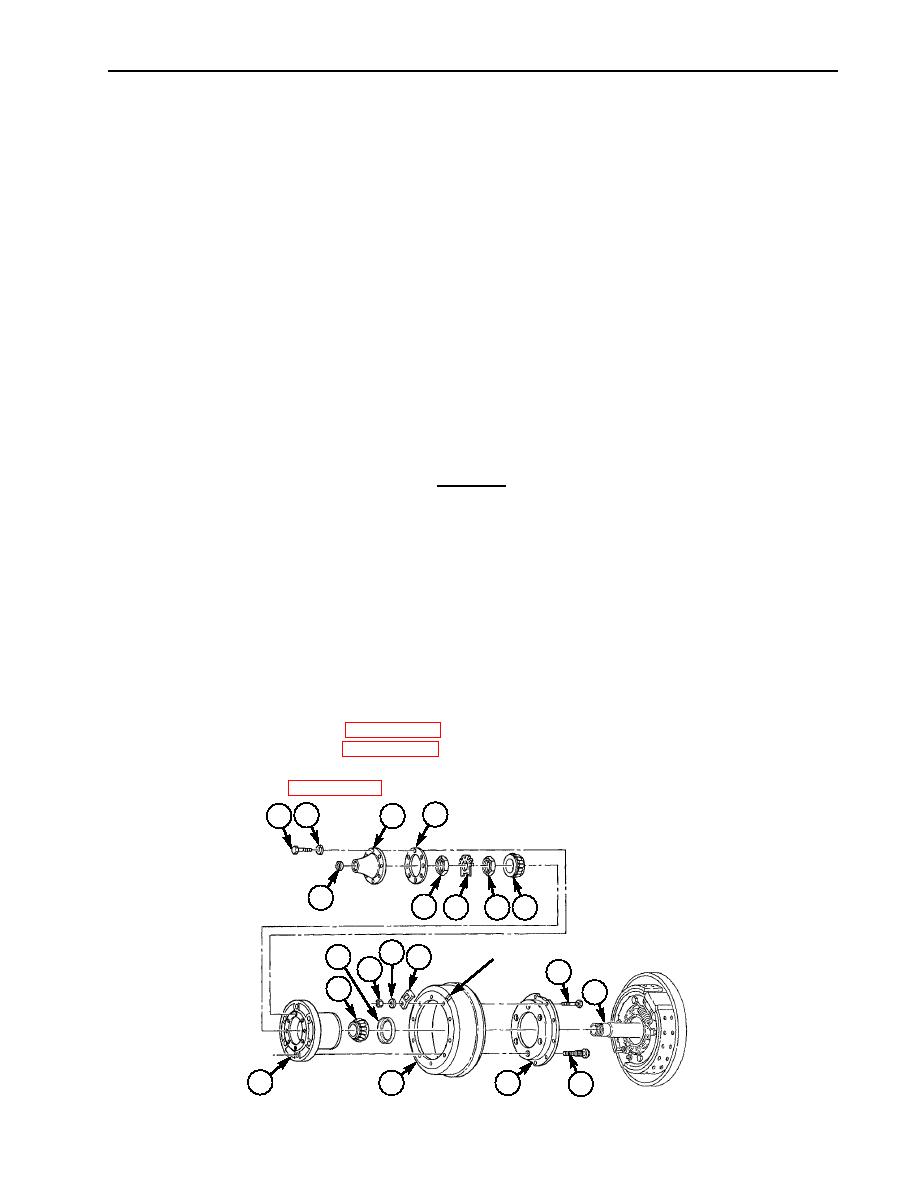

FRONT HUB AND DRUM MAINTENANCE (Contd)

LUBRICATION

1. Pack inner and outer bearings (5) and (16) with GAA grease (TM 9-214).

2. Apply light coat of GAA grease to rubber section of new inner bearing seal (12).

ASSEMBLY

NOTE

Assembly procedures below refer to one hub and drum. The

remaining hub and drum are assembled in the same way.

1.

Apply light coat of GAA grease to rubber lips of new seal (17) and lubricate bearings (5) and (16)

per TM 9-214.

2.

Install bearing (16) and seal (17) on hub (15).

3.

Install adapter (13) on drum (14) with ten new bolts (10).

4.

Position hub (15) on adapter (13), align inspection holes of hub (15) and drum (14), and install six

new wheel studs (12).

5.

Install access cover (20) (placed to cover inspection hole), ten new lockwashers (19), and nuts (18)

on bolts (10). Tighten nuts (18) 3139 lb-ft (4253 Nm).

6.

Cover threaded end of spindle (11) with tape and apply grease to spindle (11).

CAUTION

Use extreme caution when installing hub and drum on spindle.

Any jarring or sliding of hub and drum over threaded end of

spindle may cause damage to contact surfaces of spindle and hub.

7.

Install hub (15) and drum (14) on spindle (11) and remove tape from threaded end of spindle (11).

8.

Install outer bearing (5) on spindle (11) and hub (15).

9.

Install inner nut (6) on spindle (11), turn drum (14) and tighten inner nut (6) 50 lb-ft (68 Nm),

then back off nut (6) 1/16 to 1/4 turn.

10.

Install new key washer (7) and outer nut (8) on spindle (11). Tighten outer nut (8) 100150 lb-ft

(136203 Nm).

11.

Bend tabs on key washer (7) down, over nut (6).

12.

Coat one side of new gasket (4) with GAA grease and align over holes in hub (15).

13.

Align holes in flange (3), gasket (4), and hub (15). Install flange (3) with expansion plug (9) on

hub (15) with eight new lockwashers (2) and screws (1). Tighten screws (1) 6080 lb-ft (81108 Nm).

14.

Install front axle shaft flange (WP 0146 00).

15.

Connect battery ground cable (WP 0126 00).

16.

Remove real wheel chocks (TM 9-2320-361-10).

17.

Install front wheel(s) (WP 0186 00).

4

2

1

3

9

8

7

6

5

19 20

INSPECTION HOLE

17

18

10

16

11

15

14

13

12

END OF WORK PACKAGE

0187 00-3/4 blank

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |