|

|||

|

|

|||

|

Page Title:

ROCKER ARMS AND PUSHRODS MAINTENANCE - continued |

|

||

| ||||||||||

|

|

TM 9-2320-361-24-1

0031 00

ROCKER ARMS AND PUSHRODS MAINTENANCE (Contd)

ROCKER ARM DISASSEMBLY

NOTE

Prior to removal, tag all components for assembly.

1.

Remove retainer (18) and thrust washer (17) from shaft (14). Discard retainer (18).

2.

Remove rocker arm (16) from support (8) and shaft (14).

3.

Remove retainer (1) and thrust washer (2) from shaft (14). Discard retainer (1).

4.

Remove rocker arm (3), support (4), rocker arm (5), spring (6), rocker arm (7), support (12), rocker

arm (11), spring (10), rocker arm (9), and support (8) from shaft (14).

5.

Remove nut (19) from adjustment screw (20).

6.

Remove adjustment screw (20) from rocker arm (16).

7.

Repeat steps 5 and 6 for each rocker arm (3), (5), (7), (11), and (9), as necessary.

CLEANING AND INSPECTION

1.

For general cleaning and inspection instructions, refer to WP 0021 00.

2.

Remove oil deposits from oil passages inside components.

3.

Inspect dowel pin (15) in shaft (14) for looseness. Replace if loose.

4.

Inspect two plugs (13) in shaft (14) ends for evidence of oil leakage. Replace if oil leakage

is present.

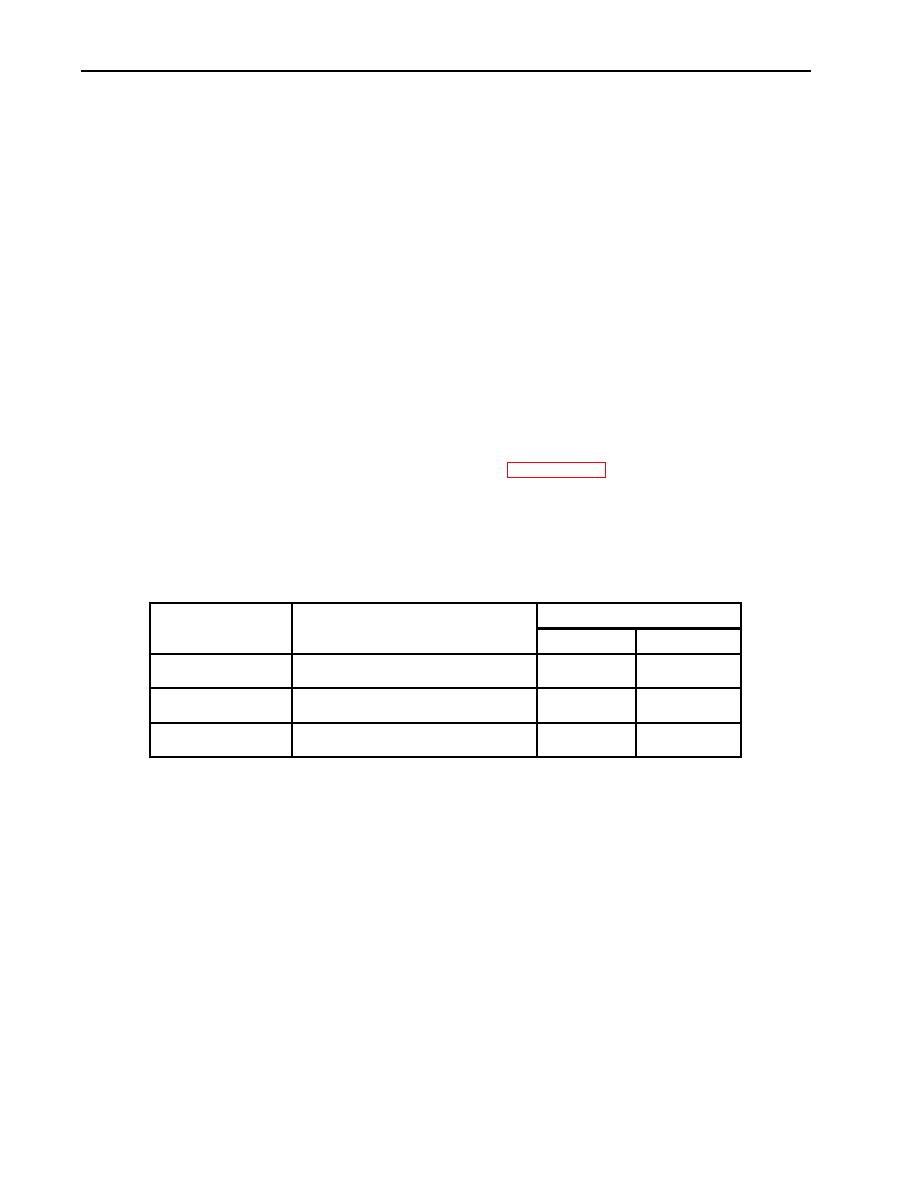

Table 1. Rocker Arm Assembly Wear Limits.

WEAR LIMIT/TOLERANCE

ITEM NO.

ITEM/POINT OF MEASUREMENT

INCHES

MILLIMETERS

3, 5, 7, 9, 11, 16

Rocker arms (inside diameter)

0.981.02

24.8925.90

4, 8, 12

Supports (inside diameter)

0.991.01

25.1425.65

14

Shaft (outside diameter)

0.971.01

24.6325.65

5.

Inspect shaft (14) for scoring or wear. Refer to table 1, Rocker Arm Assembly Wear Limits, for

measurements. Replace if damaged or worn past limits.

6.

Inspect supports (4), (12), and (8) for surface scoring or wear on shaft and rocker arm riding

surfaces. Refer to table 1, Rocker Arm Assembly Wear Limits, for measurements. Replace if

damaged or worn past limits.

7.

Inspect rocker arms (3), (5), (7), (11), (9), and (16) for surface scoring or wear on shaft and support

riding surfaces. Refer to table 1, Rocker Arm Assembly Wear Limits, for measurements. Replace if

damaged or worn past limits.

8.

Inspect rocker arms (3) (5), (7), (11), (9), and (16) for thread or valve stem riding surface damage.

Replace if damaged.

9.

Inspect thrust washers (2) and (17) for cracks or grooving. Replace if damaged.

10.

Inspect springs (6) and (10) for distortion. Replace if damaged.

11.

Inspect six pushrods (21) for scored or grooved ends and sides, cracks, and straightness. Replace if

damaged.

12.

Inspect six adjustment screws (20) for head damage, grooving, or scoring. Replace if damaged.

0031 00-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |