|

|||

|

|

|||

|

Page Title:

Table 3. Compressed Air Troubleshooting Procedures - continued |

|

||

| ||||||||||

|

|

TM 9-2320-361-24-1

0010 00

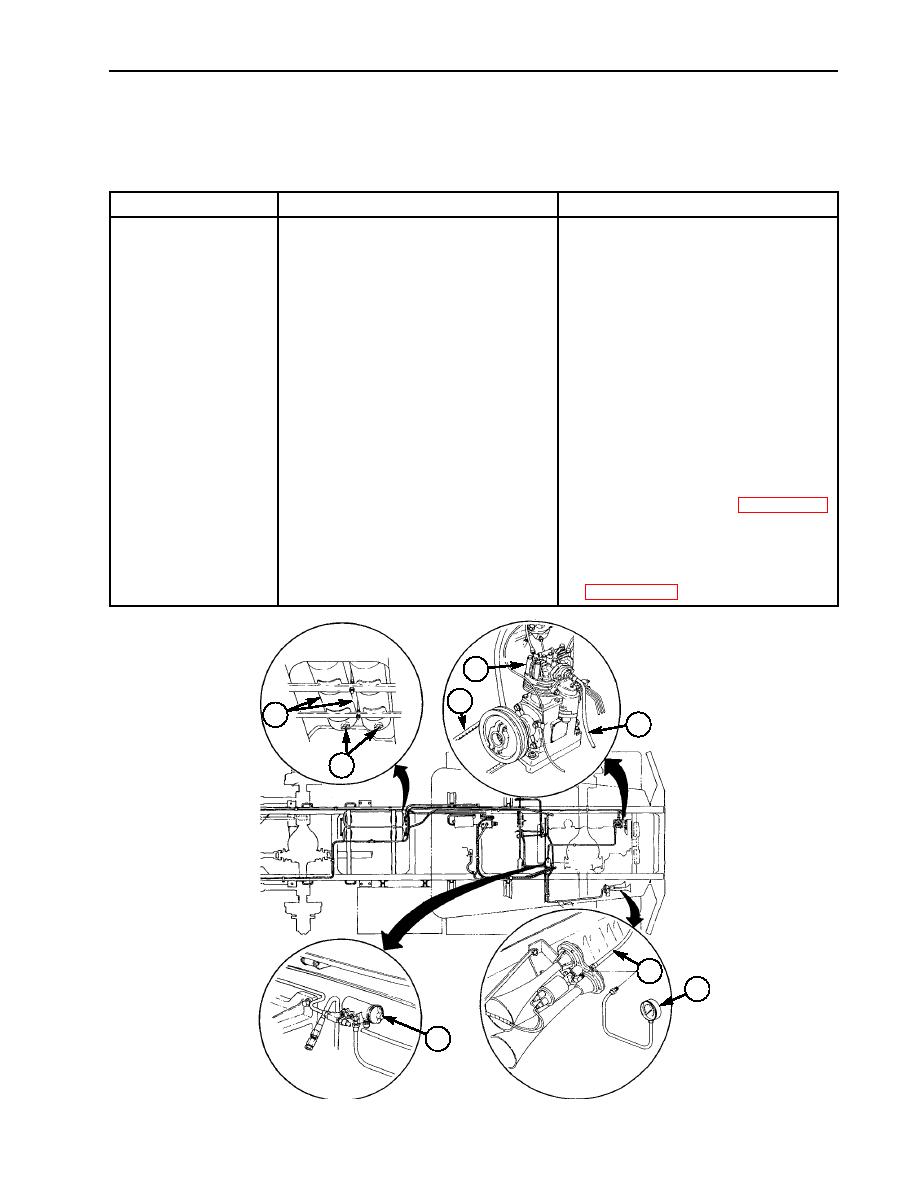

COMPRESSED AIR AND BRAKE SYSTEM TROUBLESHOOTING (Contd)

Table 3. Compressed Air Troubleshooting Procedures (Contd).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

NOTE

1. NO AIR PRESSURE

OR COMPRESSED

Air pressure gauge on instrument panel

AIR READS BELOW

has a maximum pressure reading of 120

60 PSI (LOW AIR

psi. If old governor has been replaced

PRESSURE

with new governor, air pressure may

WARNING BUZZER

exceed maximum pressure reading on

SOUNDING,

instrument panel gauge.

INDICATING AIR

1. If low or no air pressure is

5. Compare test gauge (8)

PRESSURE NOT

indicated on test gauge (8), check

reading with gauge on

BUILDING UP TO

air horn supply line (7) for

instrument panel.

NORMAL

restrictions or leaks. Repair or

OPERATING RANGE

replace damaged compressed air

AS INDICATED

lines (TM 9-243).

BY GAUGE)

2. If air compressor (4) is continuously

(Contd)

unloading, not allowing air

compressor (4) to build air pressure,

adjust air governor (6) (WP 0183 00).

3. If air governor adjustment (6) will

not increase pressure and/or

compressor outlet line (5) is warm

or cool, replace air compressor (4)

4

3

1

5

2

7

8

6

0010 00-13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |