|

|||

|

|

|||

|

Page Title:

Table 1. Engine Troubleshooting Procedures - continued |

|

||

| ||||||||||

|

|

TM 9-2320-361-24-1

0008 00

MECHANICAL SYSTEMS TROUBLESHOOTING - DIRECT SUPPORT (Contd)

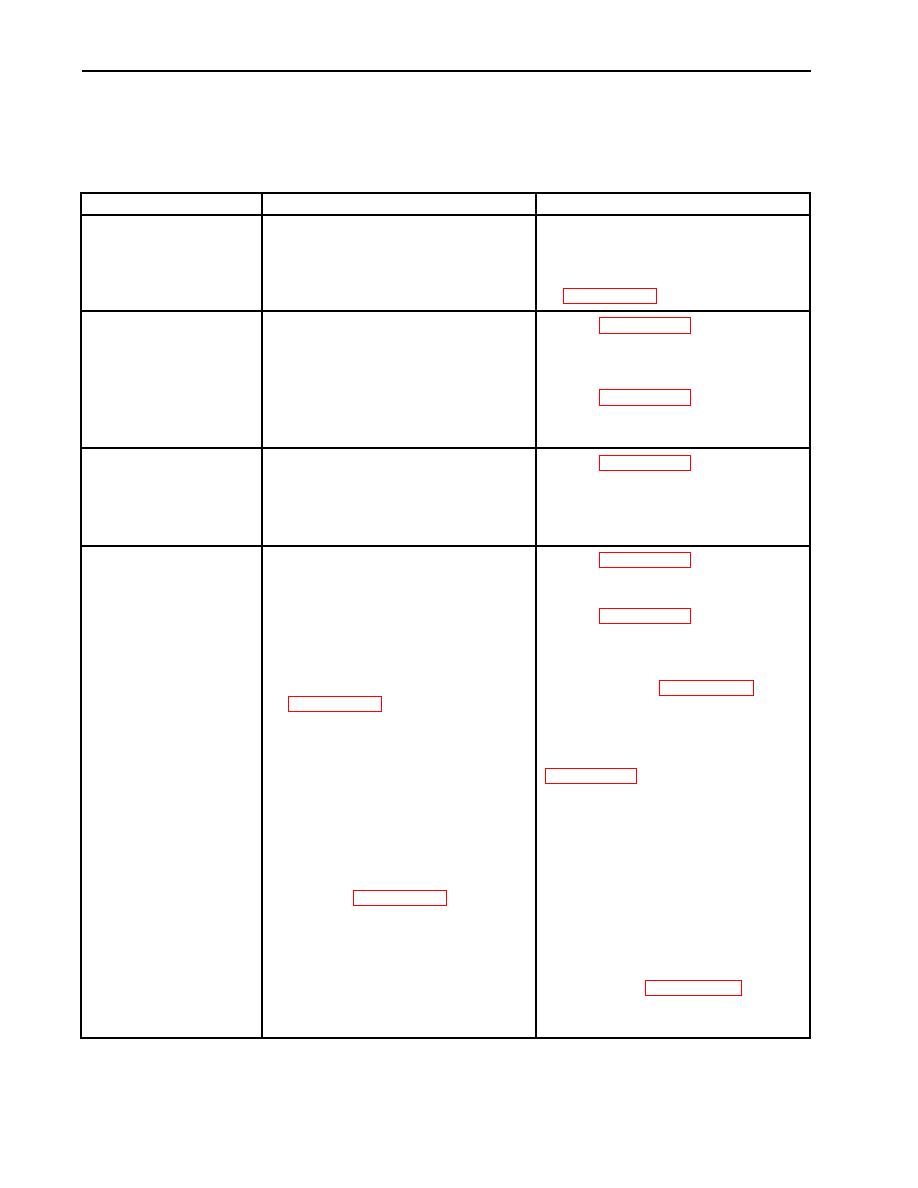

Table 1. Engine Troubleshooting Procedures (Contd).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

2. If wet compression readings

3. ENGINE CRANKS

increase 50 psi (345 kPa) or more,

BUT WILL NOT START

piston rings or cylinder bores may

(Contd)

be worn. Replace engine

1. Check fuel leakage at inlet side of

Refer to WP 0008 00, table 2,

4. ENGINE STARTS BUT

fuel supply pump (mounted on

malfunction 1, step 4. Replace

STOPS WHEN

fuel injection pump).

defective components.

ACCELERATOR IS

OPERATED

Refer to WP 0008 00, table 2,

2. Check fuel delivery system for

malfunction 1. Replace defective

defective components.

components.

Check fuel delivery system.

Refer to WP 0008 00, table 2,

5. ENGINE STOPS

malfunction 1. Replace defective

WHEN

components.

ACCELERATOR IS

RETURNED TO IDLE

POSITION

1. Check vehicle clutch system for

Refer to WP 0008 00, table 4,

6. POOR

slippage.

malfunction 2. Replace defective

components.

AND/OR LACK OF

POWER

2. Check fuel delivery system for

Refer to WP 0008 00, table 2,

defective parts.

malfunction 1, steps 15. Replace

defective parts.

3. Check fuel injection pump timing

If fuel injection pump timing is

is set within specifications

incorrect, adjust (WP 0069 00).

4. Check turbocharger operation.

If no gauge movement or only a

Remove plug from top of inlet

small pressure increase by gauge is

manifold. Install low pressure

evident, replace turbocharger

gauge with adapter into plug

opening. Start engine and

accelerate engine to full throttle

and immediately decelerate.

Observe pressure gauge readings.

5. Check turbocharger outlet, hose,

1. Tighten base screw and clamps.

intake manifold elbow and gasket

Replace missing components.

for leaks (WP 0057 00).

2. If no improvement during test

run, remove and inspect

turbocharger hose, intake

manifold elbow, and gaskets for

defects. Replace defective

components (WP 0057 00).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |