|

|||

|

|

|||

|

Page Title:

Inspection and Repair - continued |

|

||

| ||||||||||

|

|

TM 9-2320-209-34-2-3

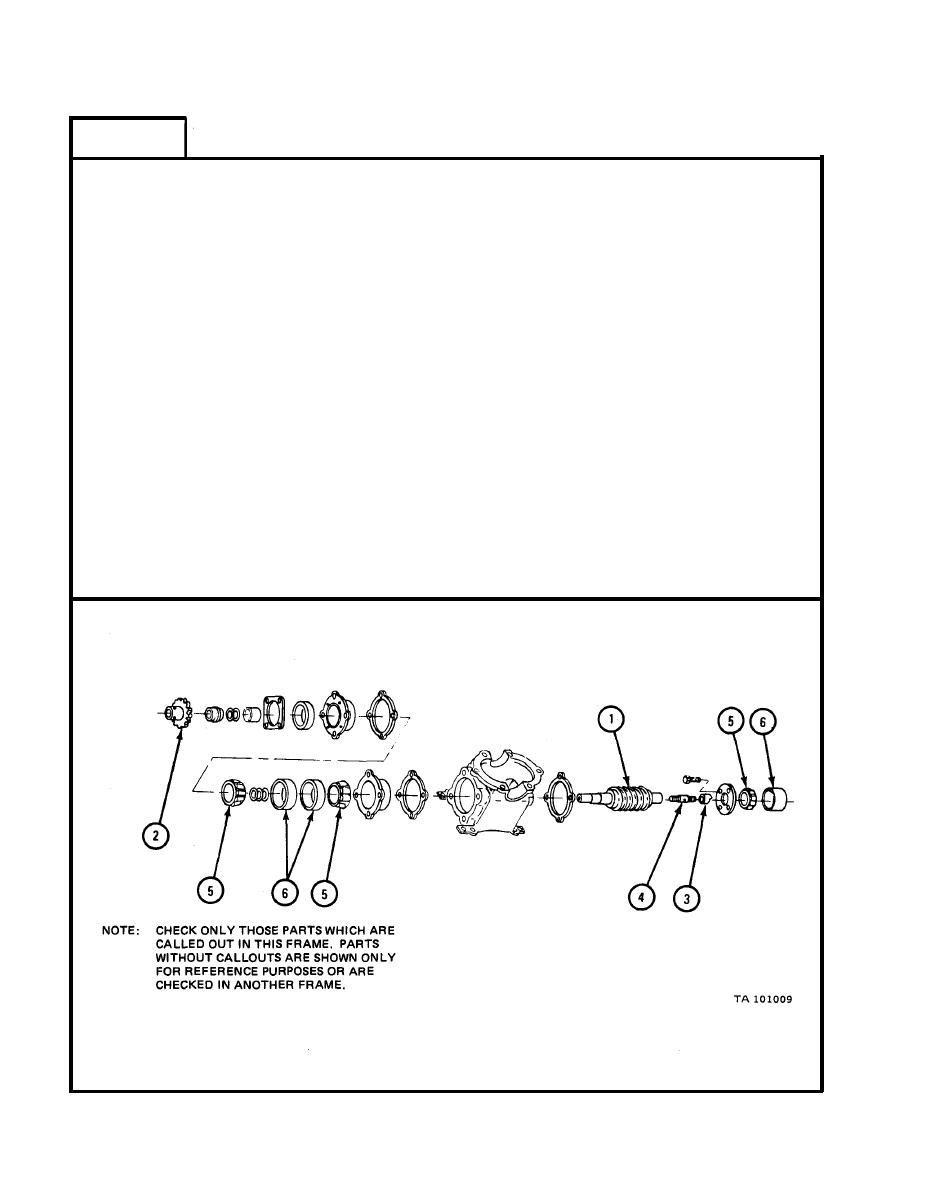

FRAME 10

Check that worm (1) and sprocket (2) have no sharp fins or burrs at

1.

tooth corners. If worm and sprocket are damaged, get new ones. Smooth

out small damage with a honing stone.

NOTE

If new worm (1) is being put in, you must order worm

assembly, consisting of worm (1), collar (3), and

stud (4).

Check that worm (1) and sprocket (2) is not cracked. If worm (1) and

2.

sprocket (2) are cracked, get new ones.

Check that worm (1) and sprocket (2) have no chipped or broken teeth.

3.

If any teeth are damaged, get new worm and sprocket.

Put clean oil ICE, OE/HDO 10, MIL-L-2104 on each bearing (5 and 6) and

4.

turn slowly by hand. The bearing must turn without binding. If bearing

assemblies are worn or damaged, get new ones.

Check that bearing rollers (5) are not grooved, pitted, or flattened. If

5.

bearing rollers are worn or damaged, get new ones.

Check that bearing cups (6) are not scored and pitted. If bearing cups are

6.

damaged, get new ones.

GO

TO FRAME 11

18-110

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |