|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-209-34-2-3

c. Cleaning. There are no special cleaning procedures needed. Refer to clean-

ing procedures given in Part 1, para 1-3.

d.

Inspection and Repair.

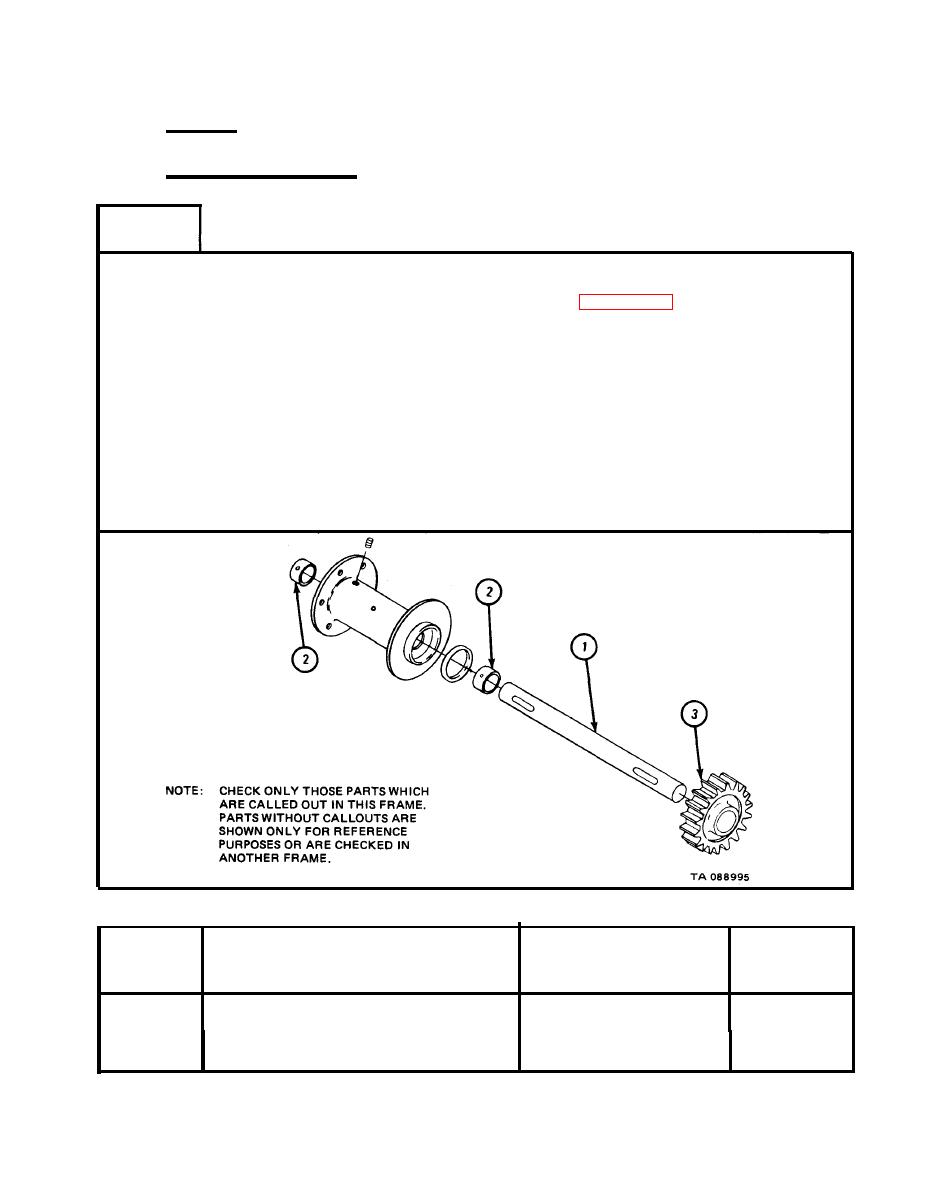

FRAME 1

NOTE

Readings must be within limits given in table 18-1. If

readings are not within given limits, throw away part

and get a new one.

1.

Check that drum shaft (1) has no nicks or burrs. Take off nicks and burrs

with a honing stone. If more repair is needed, throw shaft away.

Measure outer diameter of drum shaft (1).

2.

Measure inside diameter of two drum bushing type bearings (2).

3.

Check that teeth of drum shaft gear (3) are not broken, chipped or scored.

4.

If gear is damaged, get a new one.

GO TO FRAME 2

Table 18-1. Front Winch (Drum Shaft and Bearing) Wear Limits

Size and Fit

Wear Limit

of New Parts

Index

(inches)

(inches)

Item/Point of Measurement

Number

1.8710

1.8730 to 1.8750

Drum shaft outer diameter

1

2

Drum bushing type bearing

1.8950

1.8770 to 1.8800

inside diameter

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |