|

|||

|

|

|||

|

Page Title:

Inspection and Repair - continued |

|

||

| ||||||||||

|

|

TM 9-2320-209-34-2-1

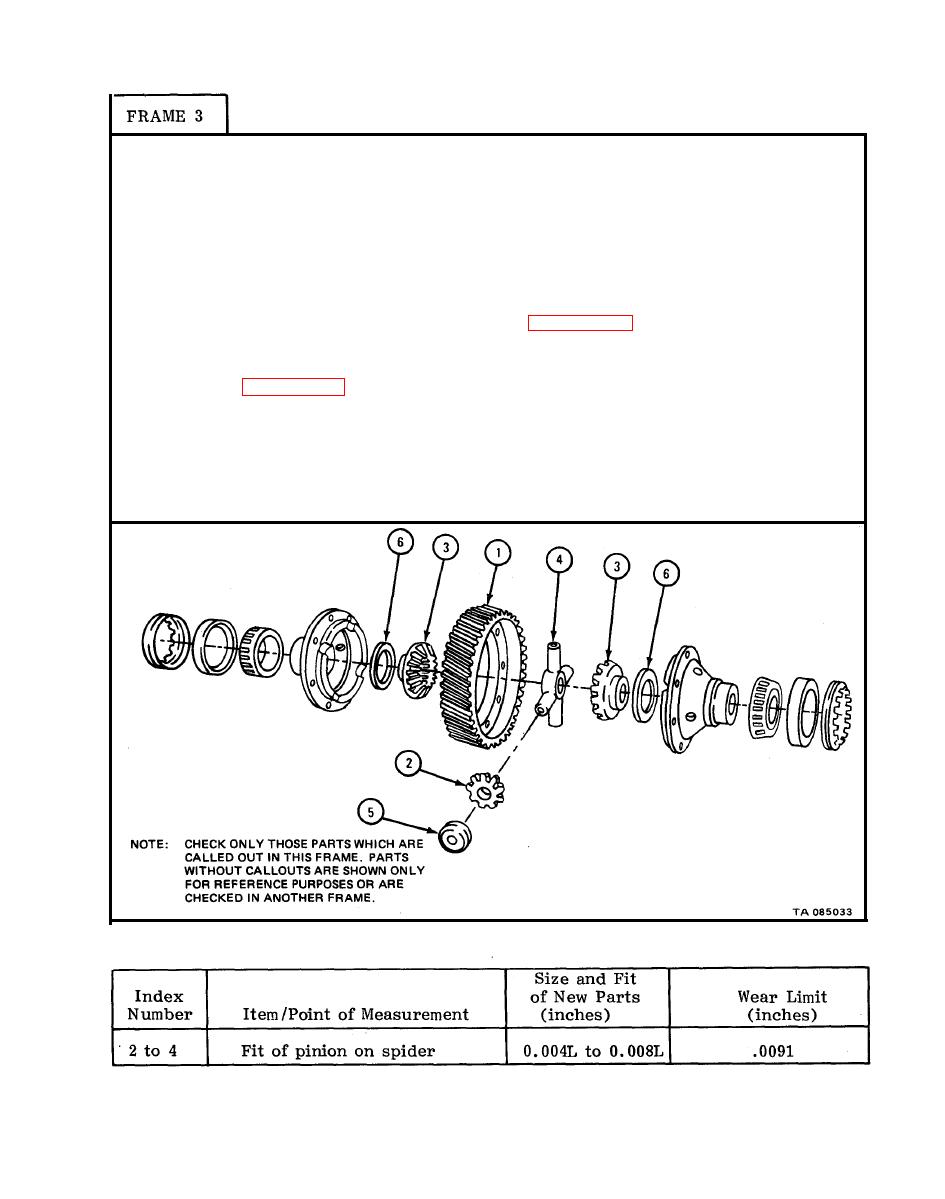

Check that teeth of helical drive gear (1), four spider gears (2), and two

1.

side gears (3) are not chipped, burred, cracked, scored or broken. Get a

new helical drive gear if it is damaged. If any one of spider gears or side

gears is damaged, get six new gears.

Check that bushings inside spider gears (2) are not pitted or damaged in any

2.

damaged.

3.

Using inside micrometer, check that inside of diameters of bushings in spider

pinion gears (2) are within limits given in table 10-6. Get new spider gears

and side gears (3) if any bushing is worn beyond limits given.

4.

Using outside micrometer, check that each arm of spider (4) is within limits

given in table 10-6. If arms are worn beyond limits given, get a new spider.

Subtract measurement in step 4 from measurement in step 3. Check that fit

5.

of pinion on spider is within limits given in table 10-6.

6.

Check that four thrust washers (5) and two thrust washers (6) are not scored

or worn unevenly. If washers are damaged, get new ones.

GO

TO FRAME 4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |