|

|||

|

|

|||

|

Page Title:

Inspection and Repair - continued |

|

||

| ||||||||||

|

|

TM 9-2320-209-34-2-1

NOTE

Readings must be within limits given in table 10-2.

If readings are not within limits, throw away parts

and get new ones.

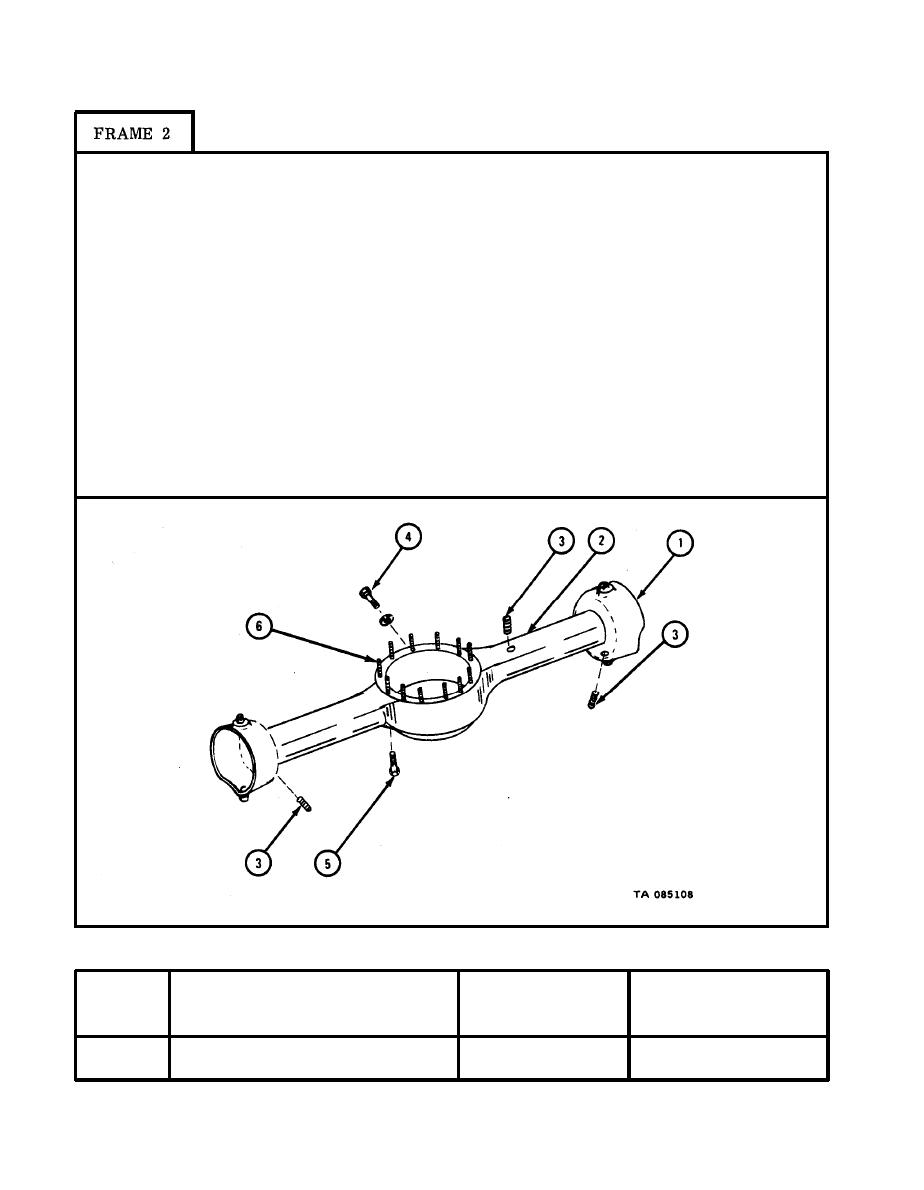

1. Measure inside diameter of seal retainer seat (1).

2. Check that axle housing (2) has no nicks, burrs or scratches and is not

bent or damaged in any other way. Rub out nicks, burrs or scratches

with a fine mill file. If more repair is needed, get a new axle housing.

3. Check that relief valves (3) are not clogged. If valves are damaged, get

new ones.

4. Check that filler plug (4), drain plug (5) and studs (6) have no stripped

threads. If parts are damaged, get new ones.

5. Check that all threaded parts are not stripped or crossthreaded.

END OF TASK

Size and Fit

Index

of New Parts

Wear Limit

Number

Item/Point of Measurement

(inches)

(inches)

1

Seal retainer seat (inside

4.245 to 4.247

4.224

diameter)

10-18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |